What is the temperature range for ultrasonic welding?

Ultrasonic welding typically operates at temperatures ranging from 20 to 40 degrees Celsius (68 to 104 degrees Fahrenheit). However, it is important to note that the temperature during ultrasonic welding is not the primary factor for achieving a successful weld.

During the ultrasonic welding process, high-frequency vibrations are applied to the materials being joined. These vibrations create friction and localized heat at the interface of the materials, causing them to soften and bond together. The heat generated during ultrasonic welding is relatively low compared to other welding methods, such as laser welding or arc welding.

The focus of ultrasonic welding is on the mechanical energy generated by the vibrations, rather than the temperature. The vibrations cause the molecules of the materials to move and intermingle, resulting in molecular bonding and the formation of a solid-state weld. This mechanical energy is what provides the strength and integrity of the weld.

The temperature rise during ultrasonic welding is generally minimal and localized to the immediate vicinity of the weld interface. It is important to control the duration and intensity of the vibrations to prevent excessive heating that could potentially damage the materials or affect the quality of the weld.

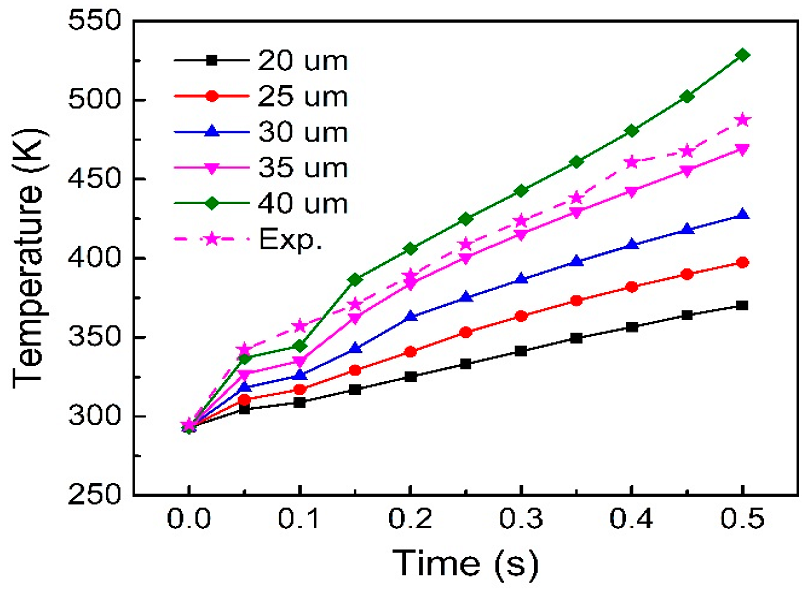

The specific temperature reached during ultrasonic welding can vary depending on factors such as the materials being welded, the design of the joint, and the welding parameters. Different materials have different melting points, and the temperature during ultrasonic welding should remain below the melting point of the materials to avoid any adverse effects.

In addition to temperature, other factors such as pressure, amplitude, and welding time also play important roles in achieving a successful ultrasonic weld. These parameters are carefully controlled to ensure proper bonding and avoid any defects in the weld.

It is worth mentioning that the temperature range for ultrasonic welding can be influenced by external factors such as the ambient temperature and the thermal conductivity of the materials being welded. Higher ambient temperatures may result in a slightly higher temperature during the welding process.

Furthermore, the temperature range for ultrasonic welding can also depend on the specific requirements of the application. For example, in certain industries such as medical or food packaging, strict temperature regulations may be in place to ensure product safety and compliance with industry standards.

To determine the optimal temperature range for a particular ultrasonic welding application, it is recommended to consult the equipment manufacturer's guidelines and conduct process optimization experiments. These experiments can help identify the temperature range that provides the best balance between achieving a strong weld and avoiding any negative effects on the materials.

In conclusion, while the temperature during ultrasonic welding is not the primary focus, the process typically operates at temperatures ranging from 20 to 40 degrees Celsius (68 to 104 degrees Fahrenheit). The mechanical energy generated by the vibrations is the key factor in achieving a successful weld. By controlling the duration, intensity, and other parameters of the vibrations, the temperature rise can be minimized, ensuring the integrity and quality of the ultrasonic weld.

If you have any more questions or need further clarification, please feel free to ask.