Washing Machine Dispenser Hot Melt Welder

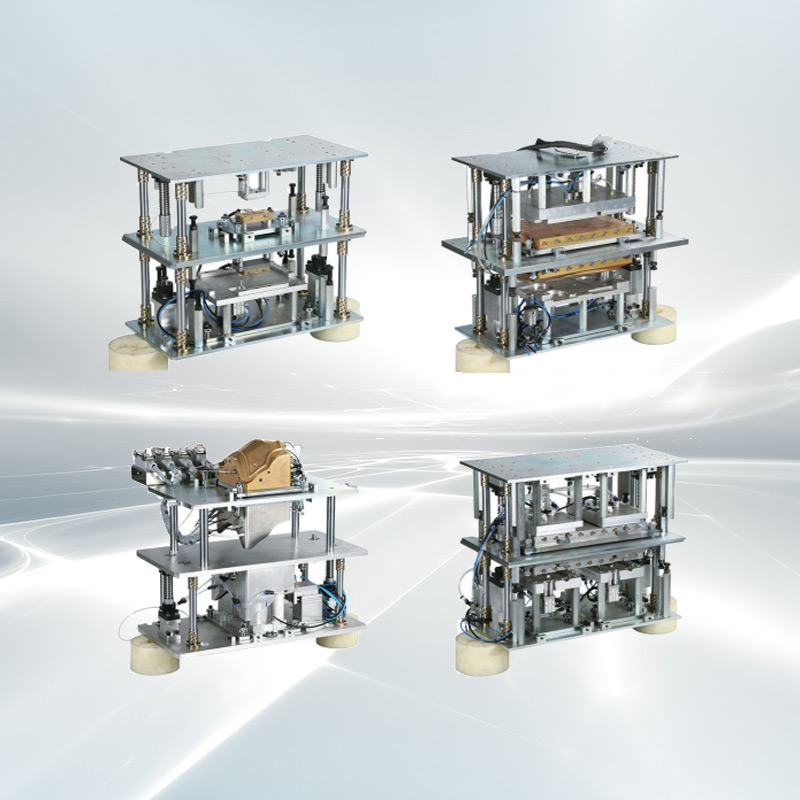

NC-2040/NC-3040/NC-5060 Hot Plate Welder

Introducing our state-of-the-art Dizo Hot Melt Welding Machine, a CE-certified solution backed by 10 years of technical support and trusted by over 500 plastic factories worldwide. This advanced system features dual-pressure control, IoT diagnostics, and delivers high-precision performance across a 5000mm² working area. Our eco-friendly design achieves zero waste and 20% energy savings while maintaining ISO 14001 certification.

Specifically designed for washing machine dispenser components, our hot melt welding machine system creates seamless, durable bonds for various plastic materials including PP, PC, and PC/ABS, requiring no additional welding materials. The hot melt welding machine features a standard mold interface for quick tool changes, optimizing production workflow and maximizing efficiency. Built with durability in mind, the hot melt welding machine system incorporates A3 cold-rolled steel construction and includes protective safety guards for automatic welding operations.

Our comprehensive service package includes 24-hour technical support, free consultation, and guidance. The hot melt welding machine's versatile design, featuring adjustable casters for precise leveling and height adjustment, makes it adaptable to various production requirements. We're currently seeking global agent partners to expand our market presence, offering custom solutions for automotive, home appliances, and medical parts manufacturing with precision down to 0.01mm.

Request for Quote- Features |

- Cases & Parameters |

- Certification |

- Copperation Steps |

- Advantages |

- Packaging |

- Solution |

- Appilications |

- Reviews

Plastic Hot Melt Welding Machine Features

Hot plate welding uses electric heat melting, where a heating plate heats specific parts of the washing machine dispenser that require welding. The heating plate's temperature is precisely controlled to melt the parts to the optimal degree. The two workpieces are then joined under controlled pressure to complete the weld.

The washing machine dispenser welder feature imported PLC programmable microcomputer control systems that ensure easy operation and consistent fusion. The precise control of welding parameters and adjustable equipment configurations enables a highly automated and intelligent welding process for plastic dispenser.

The hot melting Welding machine's active mold-locking design simplifies the process of changing upper and lower molds. This reduces production costs and enhances equipment flexibility, allowing for easy adaptation to different washing machine dispenser models and specifications.

This hot melt welding method excels at joining large and specialized plastic workpieces like washing machine dispenser. The technology delivers rapid welding speeds, strong bonds, and excellent sealing properties—all crucial factors in ensuring high-quality, reliable washing machine dispenser assembly.

Washing Machine Dispenser Welding Cases

Plastic Hot Melt Welder Parameters

| Type | Standard Pneumatic Plastic Dispenser Hot Melt Welder | Servo Plastic Dispenser Hot Melt Welder | Quick-Change Servo Plastic Dispenser Hot Melt Welder |

|---|---|---|---|

| Model | DZ-350 | DZ-800S | DZ-1000SF |

| Equipment Dimension | W1400*L1500*H2100mm | W2000*L2200*H2600mm | W2200*L2400*H2800mm |

| Voltage | 380V | 380VAC | 380VAC |

| Maximum Welding Size | 350*200mm | 800*450mm | 1000*600mm |

We are Internationally Certified

Our hot plate welding machines for washing machine plastic dispenser are certificated with CE,ISO and ROSH. They all meet international standards. These hot melt welding solutions blend precision with versatility, creating perfect welds for plastic components made from thermoplastic materials including PP, PE, ABS, PC, PET, PMMA, PVDF and PVC.

Purchasing Guide: Plastic Dispenser Hot Melt Welding Machines

We provide comprehensive plastic welding solutions for washing machine dispenser. Follow these steps to complete the process:

-

STEP 1

Sample Evaluation

Review washing machine dispenser requirements and technical specifications.

-

STEP 2

Feasibility Study

Analyze the feasibility of the welding techniques for the washing machine dispenser application.

-

STEP 3

Prototype Development

Create and test prototypes based on the evaluated dispenser samples.

-

STEP 4

Customer Approval

Present the prototype to gather feedback and secure customer approval.

-

STEP 5

Quotation

Issue a detailed quotation for the selected hot melt welding machine.

-

STEP 6

Order Confirmation

Finalize the order and confirm all specifications.

-

STEP 7

Manufacturing Process

Manufacture the hot melt welding machine according to the confirmed order details.

-

STEP 8

Quality Assurance

Conduct thorough quality checks to ensure the hot melt welding machine meets all standards.

-

STEP 9

Delivery and Installation

Deliver the welding machine and complete installation at the customer's site.

-

STEP 10

Training and Support

Provide training and ongoing support to ensure smooth operation of the equipment.

Custom Dizo Plastic Dispenser Hot Melt Welder Advantages

Works with Any Size

Hot melt welding fits all sizes of washing machine dispenser plastic parts without area limits.

Any Surface Works

Washing machine dispenser hot melt welders can weld any type of surface easily.

Strong and Adaptable

Can be adjusted to different shapes while staying strong.

Customized for Each Material

Suit different materials, keeping it precise and easy to control.

Packaging for Plastic Hot Melt Welding Machine

Hot Melt Welding Solutions in Plastic Welding Industry

Hot melt welding machines are trusted solutions in the plastic welding industry, creating strong and reliable bonds across diverse applications. These machines excel at complex welding tasks and serve multiple industries—automotive manufacturing, household appliances, environmental filtration products, electronics, plastic toys, audiovisual products, and packaging.

Dizo's hot melt welding machines feature advanced systems engineered for durability, efficiency, and seamless production line integration. They consistently deliver superior weld strength and quality on both flat and curved surfaces, ensuring reliable results every time.

Learn More

Other Hot Melt Welding Applications

Hot Melt welding works best with thermoplastics (PP, PE, ASA, ABS, POM, PA, PBT, PC, PET, PMMA, PVDF, PVC, PS, PPO etc.) for large complex pieces, offering strong joints, excellent sealing, thick-wall compatibility, and clean welds. Used across industries, it's vital in automotive for waterproof irregular parts, appliance manufacturing for housings, storage container production, and medical equipment assembly.

Customer Reviews

Quote Now

Quote Now