Ultra sonic Plastic Welder With Table

NC-E Ultrasound Welder Series

● Portable Welding Capabilities:

The ultra sonic welding machine features an ergonomic design for easy transport between work sites, allowing operators to perform precise welding at multiple locations with quick setup. Its compact size and built-in handles make moving simple.

● Advanced Noise Reduction Technology:

Built with high-grade acoustic dampening materials and sound-absorbing panels, the ultrasonic plastic welder system provides excellent noise control. The multi-layer insulation reduces noise by about 60 decibels, ensuring a quieter workspace while maintaining clear communication.

● Comprehensive Safety Systems:

The pneumatic control system uses smart motion control to regulate speeds and automatically slow movement at endpoints. These safety features, along with emergency stops, protect workers near moving parts and doors.

● Intuitive User Interface and Design:

The ultrasound welder system features a clean, well-engineered exterior with appealing industrial styling. Its modular design enables easy maintenance access, while the straightforward control layout improves efficiency.

● Enhanced Customization and Compliance Features:

The ultrasound welder system offers multiple configuration options to suit various machine setups and models. The adaptable design complies with international safety and quality standards, including CE and FCC certifications..

Request for Quote- Features |

- Parameters |

- Certification |

- Advantages |

- Packaging |

- Appilications |

- FAQs |

- Reviews

Ultrasonic Plastic Welder Features

The ultra sonic welding machine is advanced welding equipment that offers high efficiency, precision, and smart automation.

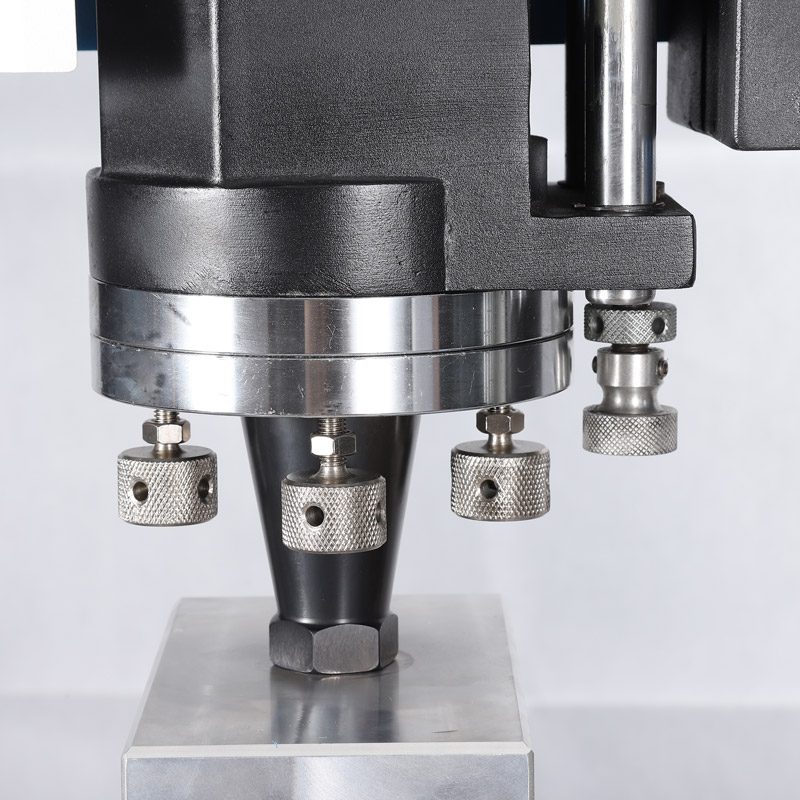

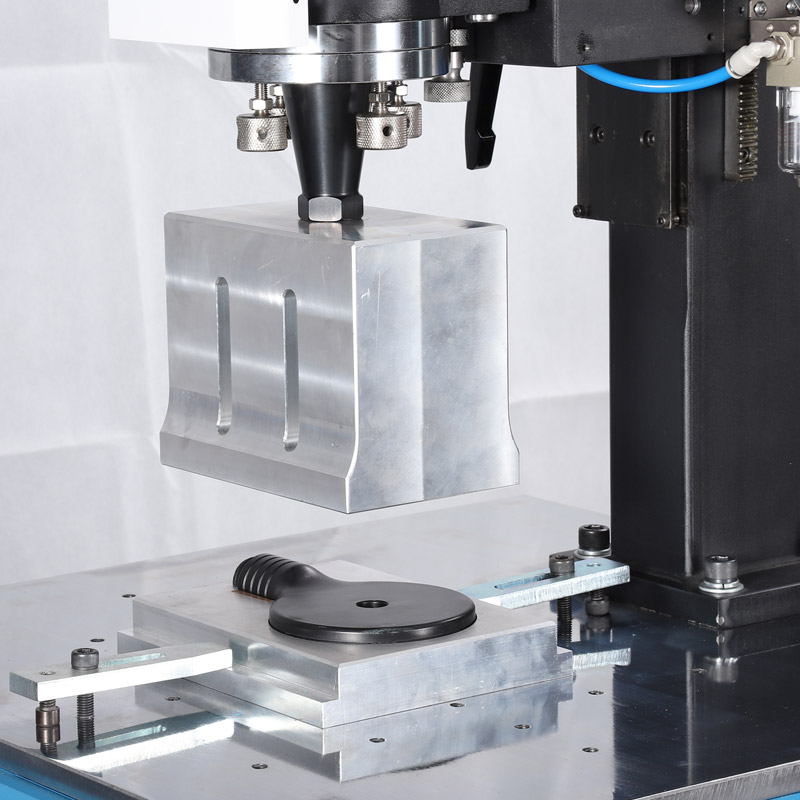

The ultra sonic welding machine features Japanese transducers for precise, stable frequency control. Its key components—including transducers and amplitude transformers—are built with high-quality materials for maximum durability and stability. The pneumatic system incorporates Taiwan brand cylinders and solenoid valves, while electronic components are sourced from European and American suppliers, ensuring superior performance and reliability.

For ease of operation, the ultra sonic welding machine uses microcomputer control with parameters entered via external buttons and displayed on an LCD screen. Built-in overvoltage and overcurrent protection systems help prevent malfunctions and ensure safe operation.

This ultra sonic welding machine specializes in precision electronics applications, including small plastic casings, power plugs, USB drives, and phone case lenses. It uses an ultrasonic high-frequency vibrating welding head that creates frictional heat between two plastic pieces under moderate pressure. This results in instant fusion bonding that matches the strength of the base material. The ultra sonic welding process delivers both efficient, clean welds and ensures water-tight and air-tight seals.

Ultrasonic Plastic Welder Parameters

| Parameters | |||

|---|---|---|---|

| Model | DZ-1532E | DZ-1542E | DZ-1555E |

| Frequency | 15KHZ | 15KHZ | 15KHZ |

| Power | 3200W | 4200W | 5500W |

| Voltage | 220V | 220V | 220V |

| Amplitude Adjustment | 10%-100% accuracy adjustable, minimum adjustment accuracy 1% | ||

| Working Temperature | -10℃ - 40℃ | ||

| Weight | 300KGS | 350KGS | 400KGS |

| Size | 80*90*200CM | 90*100*220CM | 90*100*220CM |

We are Internationally Certified

Our plastic ultra sonic welding machines are certificated with CE,ISO and ROSH. They all meet international standards.

Custom Plastic Ultra Sonic Welding Machine Advantages

Ultra sonic welding has several advantages as below.

-

High Efficiency

Ultrasound welding needs no preheating, ensuring fast speeds suitable for mass production, thereby boosting efficiency.

-

Reliable and Stable

The ultrasound welding process is highly controllable, resulting in strong welds and consistent product reliability.

-

Environmentally Friendly

It uses no adhesives or solvents, saves energy, and meets environmental standards.

-

Easy Operation

High automation makes it easy to operate and maintain, ideal for complex tasks and reducing labor costs.

Packaging for Ultrasonic Plastic Welder

Plastic Ultra Sonic Welding Machine for Different Industries

Ultra sonic welding Machine is widely used in welding plastic products, including industries automotive, consumer electronics, medical, toys, packaging, and so on, especially where long-lasting, strong, and great-looking connections are needed.

FAQs

Here are frequently asked questions to consider before choosing an ultra sonic welding machine for your plastic products.

Customer Reviews

Quote Now

Quote Now