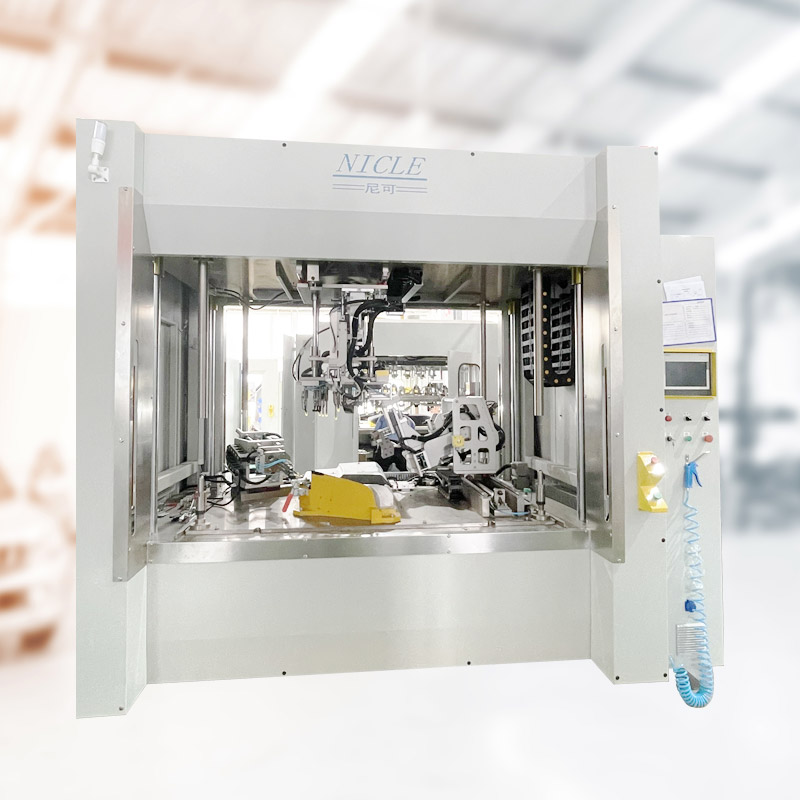

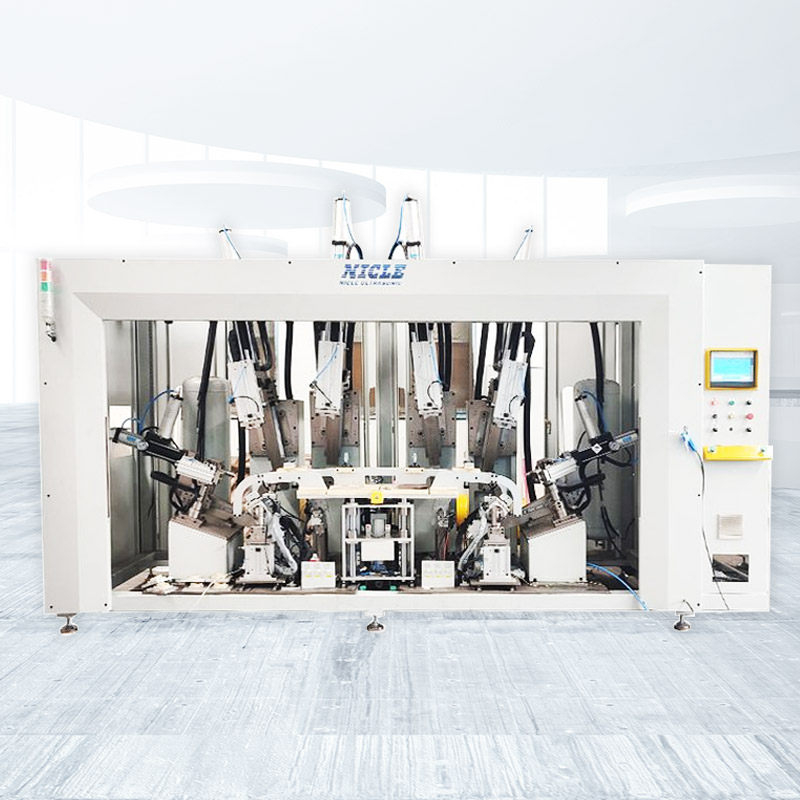

Heat Staking & Hot Fusion Welding Machine

NC Heat Staking Equipment Series

Introducing our state-of-the-art Heat Fusion Welding Machine, a CE-certified solution offering 10-year technical support and proven reliability across 500+ plastic factories. This versatile system combines advanced hot fusion and heat staking techniques, delivering exceptional performance for automotive plastic welding with seamless process transitions. Our eco-friendly design achieves zero waste and 20% energy savings, while maintaining ISO 14001 certification and incorporating servo-driven technology for reduced carbon footprint.

The hot fusion welding machine features sophisticated engineering with adjustable welding units equipped with buffer stop mechanisms and 360-degree positioning capabilities, allowing operators to optimize settings for various materials and scenarios. The independent head angle control system provides micrometer-level precision, particularly valuable when working with complex shapes and varying material thicknesses. Enhanced by workpiece detection sensors and an advanced alarm system, the machine prevents errors by monitoring positioning, missing parts, and misalignments before welding begins.

Our hot fusion welding machine system offers unmatched versatility with dual-pressure control, IoT diagnostics, and comprehensive on-site training. The high-precision operation covers a 5000mm² area with continuous operation capability and includes free sample testing. Real-time monitoring and adaptive controls ensure fast, consistent welding results while maintaining superior quality throughout production runs.

Request for Quote- Features |

- Certification |

- Copperation Steps |

- Advantages |

- Packaging |

- Technology |

- Appilications |

- Reviews

Heat Staking & Hot Fusion Plastic Welding Machine Features

Heat staking welding (also known as heat riveting welding) and hot fusion welding work together effectively in automotive component manufacturing. For complex or specialized welding applications, hot fusion welding first joins the main parts, ensuring strong, sealed joints. Heat staking welding then handles fine structures and hard-to-reach areas, providing precise supplementary welds. This combined approach maximizes the strengths of both heat staking and hot fusion techniques while improving flexibility and adaptability.

Regarding material compatibility, heat staking welding works with various materials - including metals and plastics - while hot plate welding specializes in plastic components. Together, the heat staking and hot fusion technologies enable efficient welding of diverse automotive components, including metal - plastic composite parts. This versatility opens new possibilities for component design and manufacturing, driving automotive innovation.

Both welding technologies offer exceptional efficiency and speed. Their combined use streamlines automotive component production. By optimizing heat staking and hot fusion welding processes and minimizing waste and wait times, manufacturers can achieve efficient mass production of automotive parts.

We are Internationally Certified

Our heat staking and hot fusion plastic welding machines are certificated with CE,ISO and ROSH. They all meet international standards. We're currently seeking global agent partners to expand our market presence, offering free consultation and guidance to support your manufacturing needs.

Purchasing Guide: Heat Staking & Hot Fusion Welding Machine

We provide comprehensive heat staking and hot fusion plastic welding solutions for automotive interior and exterior parts. Follow these steps to complete the process:

-

STEP 1

Sample Evaluation

Review car plastic part sample requirements and technical specifications.

-

STEP 2

Feasibility Study

Analyze the feasibility of the welding techniques for the specific application.

-

STEP 3

Prototype Development

Create and test prototypes based on the evaluated car plastic part samples.

-

STEP 4

Customer Approval

Present the prototype to gather feedback and secure customer approval.

-

STEP 5

Quotation

Issue a detailed quotation for the selected hot fusion welding machine.

-

STEP 6

Order Confirmation

Finalize the order and confirm all specifications.

-

STEP 7

Manufacturing Process

Manufacture the hot fusion welding machine according to the confirmed order details.

-

STEP 8

Quality Assurance

Conduct thorough quality checks to ensure the hot fusion welder meets all standards.

-

STEP 9

Delivery and Installation

Deliver the hot fusion welder and complete installation at the customer's site.

-

STEP 10

Training and Support

Provide training and ongoing support to ensure smooth operation of the hot fusion welder.

Custom Dizo Heat Staking & Hot Fusion Welding Machine Advantages

Custom Solution

Solutions customized to your specific needs, supported by 21 engineers ready to assist anytime.

Save Your Time

Full project oversight from initial requirements to final delivery, ensuring efficiency and time savings.

Guaranteed Quality Assurance

Adheres to ISO standards for consistent and reliable quality throughout the process.

Professional Service Team

A professional 20-person service team ensures seamless hot fusion plastic welder installation and complete customer satisfaction.

Packaging for Heat Staking & Hot Fusion Plastic Welding Machine

Plastic Welding Techniques in the Automotive Industry

Different welding applications demand specific approaches. Automotive companies often require a blend of ultrasonic welding systems, hot plate welders, vibration welding machines, heat staking and hot fusion hybrid solutions.

We specialize in integrating automated heat staking and hot fusion welding into automotive assembly lines, enhancing both efficiency and product quality.

Custom-designed heat staking equipment and precise positioning allow us to tackle complex tasks, such as welding large instrument clusters, resulting in superior surface finishes and precise gap control.

Ask for Quote Now

Automotive Plastic Components Welding Applications

We provide specialized hot melt plastic welding solutions for automotive components that meet all production requirements.

Customer Reviews

Quote Now

Quote Now