- Automotive Plastic Component Welders |

- Certification |

- Cooperate Steps |

- Advantages |

- Packaging |

- Techniques |

- Applications

Explore our Car Plastic Tank Hot Plate Welder for efficient hot plate welding of car plastic radiators, water tanks, fuel tanks, carbon canisters, brake fluid reservoirs, and expansion tanks. Durable and safe for PP, ABS, PE, and more.

Achieve unmatched welding strength with our car headlights, turn signals, brake lights, taillights, and fog lights hot plate welding machine: automatic cleaning, depth control, and versatile material compatibility. Get a quote.

Enhance production with Dizo Ultrasonic's heat staking machine for car door panels. Fast welding speeds, high efficiency, and excellent product consistency.

Discover high-precision automotive plastic welding & punching for car bumpers with Dizo Ultrasonic. Achieving 0.1mm punch accuracy and secure weld points. Customize yours!

We are Internationally Certified

Our custom plastic welders for automotive parts are CE, ISO, and RoHS certified, ensuring they meet all international standards.

Purchasing Guide: Custom Plastic Welding Machines for Automotive Parts

We provide comprehensive plastic welding solutions for automotive interior and exterior parts. Follow these steps to complete the process:

-

STEP 1

Sample Evaluation

Review automotive parts sample requirements and technical specifications.

-

STEP 2

Feasibility Study

Analyze the feasibility of the welding techniques for the specific automotive parts application.

-

STEP 3

Prototype Development

Create and test prototypes based on the evaluated automotive parts samples.

-

STEP 4

Customer Approval

Present the prototype to gather feedback and secure customer approval.

-

STEP 5

Quotation

Issue a detailed quotation for the selected automotive parts welding machine.

-

STEP 6

Order Confirmation

Finalize the order and confirm all specifications.

-

STEP 7

Manufacturing Process

Manufacture the automotive parts welding machine according to the confirmed order details.

-

STEP 8

Quality Assurance

Conduct thorough quality checks to ensure the machine meets all standards.

-

STEP 9

Delivery and Installation

Deliver the welding machine and complete installation at the customer's site.

-

STEP 10

Training and Support

Provide training and ongoing support to ensure smooth operation of the equipment.

Custom Automotive Part Plastic Welding Advantages

Custom Solution

Solutions customized to your specific needs, supported by 21 engineers ready to assist anytime.

Save Your Time

Full project oversight from initial requirements to final delivery, ensuring efficiency and time savings.

Guaranteed Quality Assurance

Adheres to ISO standards for consistent and reliable quality throughout the process.

Professional Service Team

A professional 20-person service team ensures seamless plastic welder installation and complete customer satisfaction.

Packaging for Automotive Plastic Component Welding Machine

Plastic Welding Techniques in the Automotive Industry

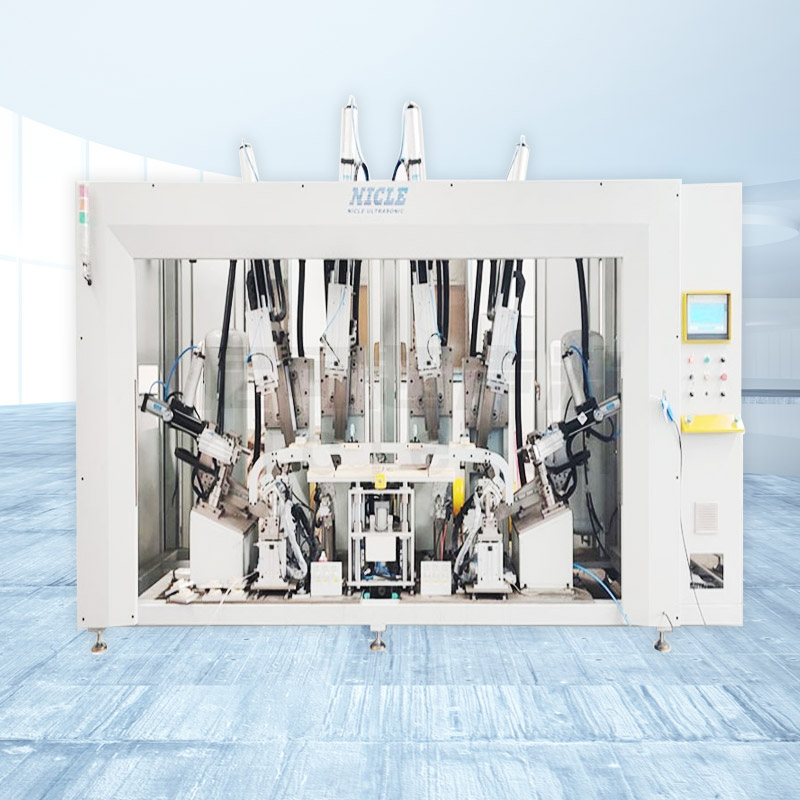

Different welding applications demand specific approaches. Automotive companies often require a blend of ultrasonic welding systems, hot plate welders, vibration welding machines, and hybrid solutions.

We specialize in integrating automated ultrasonic welding into automotive assembly lines, enhancing both efficiency and product quality.

Custom-designed ultrasonic sonotrodes and precise positioning allow us to tackle complex tasks, such as welding large instrument clusters, resulting in superior surface finishes and precise gap control.

Ask for Quote Now

Automotive Plastic Components Welding Applications

We provide specialized plastic welding solutions for automotive components that meet all production requirements.