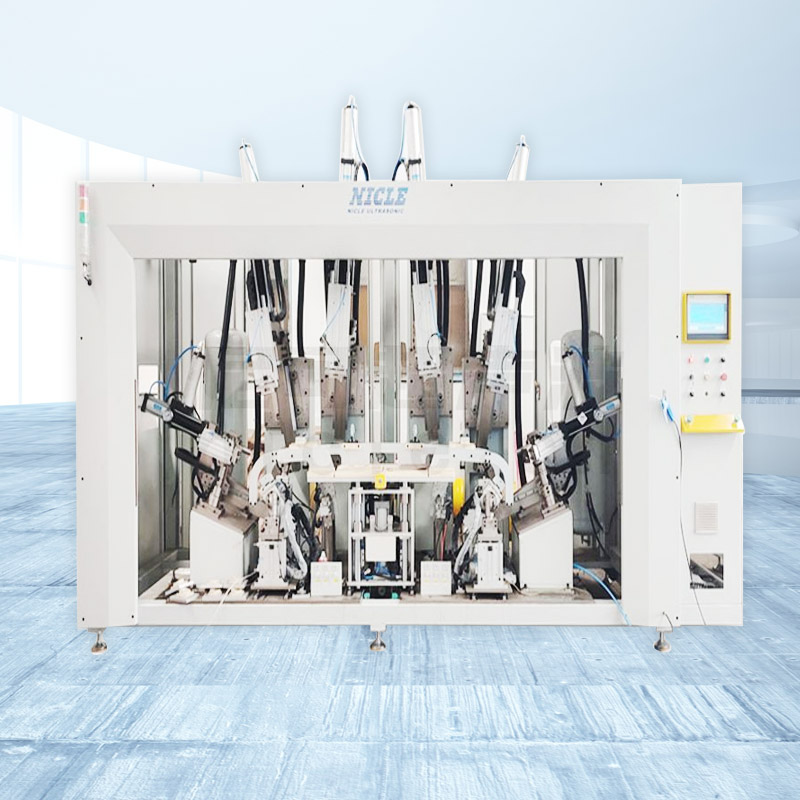

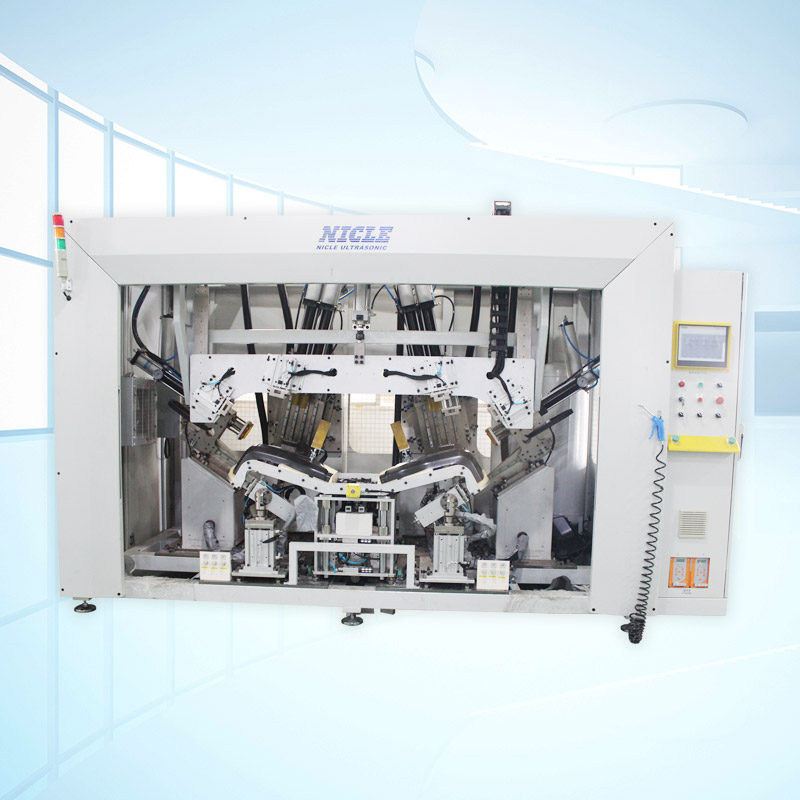

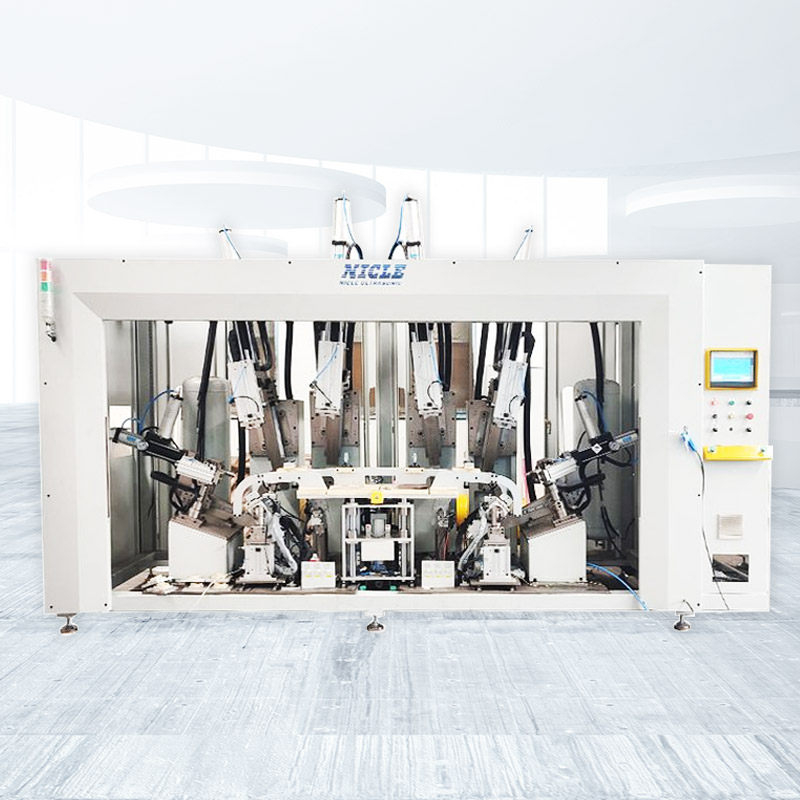

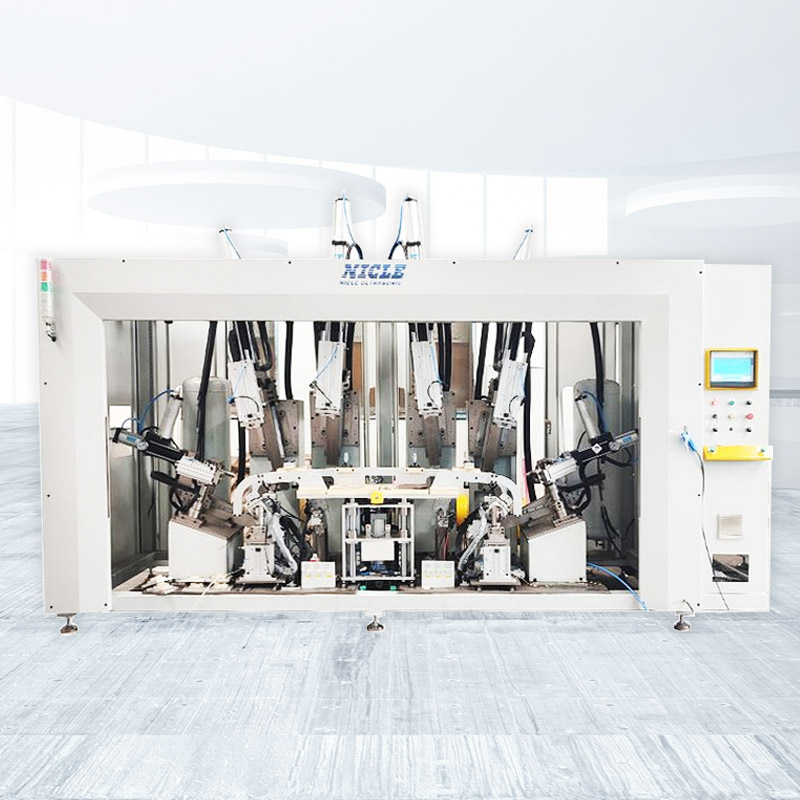

Car Bumper Ultrasonic Welding & Punching Equipment

NC Series For Exterior Components

● Flexible Weld Positioning:

Multi-head ultrasonic welding system enables complete positional freedom and easy mold modifications for diverse manufacturing needs.

● Precise Horizontal Adjustment:

CNC-machined holders with fine-thread screws provide precise positioning and consistent alignment.

● High-Precision Punching:

Advanced ultrasonic punching system delivers 0.1mm accuracy with superior R-angle capabilities while preserving paint integrity.

● Strong and Secure Welds:

Creates firm, durable welds without backside deformation or surface bulging on automotive bumpers.

● Customizable Punching Options:

Adaptable configuration system allows easy adjustment of punch quantities while maintaining quality standards.

● Conclusion:

The car bumper ultrasonic welding & punching equipment machine delivers exceptional efficiency while being environmentally friendly and energy-efficient. Its non-contact processing method eliminates the need for cutting tools or punches, substantially reducing maintenance costs. The ultrasonic welding & punching process also produces zero harmful emissions, meeting the automotive industry's strict environmental protection and sustainability standards.

Request for Quote- Features |

- Certification |

- Copperation Steps |

- Advantages |

- Packaging |

- Technology |

- Appilications |

- Reviews

Car Bumper Ultrasonic Welding Machine Features

Ultrasonic welding technology is extensively used in automotive bumper assembly. Automotive bumpers comprise multiple components that must be securely joined to create a unified structure. The ultrasonic welding process uses heat from high-frequency vibrations to melt and bond plastic materials, creating robust connections between automotive bumper components. This technique ensures both structural integrity and enhanced impact resistance. For instance, reinforcement ribs are firmly attached to the automotive bumper's main body through ultrasonic welding, strengthening the overall structure.

Ultrasonic punching machines are equally essential in bumper manufacturing. Unlike traditional methods that often produce imprecise cuts and burrs, ultrasonic punching harnesses heat from vibrational friction. The ultrasonic punching process combines cylinder pressure with ultrasonic vibration to create clean, precise holes. This efficient method delivers superior results when creating openings for radar systems and turn signals in both front and rear bumpers, accommodating all necessary manufacturing specifications.

In conclusion, ultrasonic welding and punching technologies are fundamental to modern automotive bumper production, ensuring consistent, high-quality manufacturing outcomes.

We are Internationally Certified

Our car bumper ultrasonic welding & punching equipment machines are certificated with CE,ISO and ROSH. They all meet international standards.

Purchasing Guide: Car Bumper Ultrasonic Welding & Punching Equipment

We provide comprehensive ultrasonic plastic welding & punching solutions for automotive bumper. Follow these steps to complete the process:

-

STEP 1

Sample Evaluation

Review automotive bumper sample requirements and technical specifications.

-

STEP 2

Feasibility Study

Analyze the feasibility of the welding techniques for the automotive bumper application.

-

STEP 3

Prototype Development

Create and test prototypes based on the evaluated automotive bumper samples.

-

STEP 4

Customer Approval

Present the prototype to gather feedback and secure customer approval.

-

STEP 5

Quotation

Issue a detailed quotation for the selected ultrasonic welding machine.

-

STEP 6

Order Confirmation

Finalize the order and confirm all specifications.

-

STEP 7

Manufacturing Process

Manufacture the ultrasonic welding machine according to the confirmed order details.

-

STEP 8

Quality Assurance

Conduct thorough quality checks to ensure the machine meets all standards.

-

STEP 9

Delivery and Installation

Deliver the welding machine and complete installation at the customer's site.

-

STEP 10

Training and Support

Provide training and ongoing support to ensure smooth operation of the equipment.

Custom Dizo Car Bumper Ultrasonic Welding & Punching Equipment Machine Advantages

Custom Solution

Solutions customized to your specific needs, supported by 21 engineers ready to assist anytime.

Save Your Time

Full project oversight from initial requirements to final delivery, ensuring efficiency and time savings.

Guaranteed Quality Assurance

Adheres to ISO standards for consistent and reliable quality throughout the process.

Professional Service Team

A professional 20-person service team ensures seamless plastic welder installation and complete customer satisfaction.

Packaging for Car Bumper Ultrasonic Welding Machine

Plastic Welding Techniques in the Automotive Industry

Different welding applications demand specific approaches. Automotive companies often require a blend of ultrasonic welding systems, hot plate welders, vibration welding machines, and hybrid solutions.

We specialize in integrating automated ultrasonic welding into automotive assembly lines, enhancing both efficiency and product quality.

Custom-designed ultrasonic sonotrodes and precise positioning allow us to tackle complex tasks, such as welding large instrument clusters, resulting in superior surface finishes and precise gap control.

Ask for Quote Now

Automotive Plastic Components Welding Applications

We provide specialized plastic welding solutions for automotive components that meet all production requirements.

Customer Reviews

Quote Now

Quote Now