Portable Handheld Ultrasonic Spot Welding Machine

28/35 kHz NC-E Ultrasonic Welder Series

● Enhanced Portability:

The lightweight yet durable equipment enables precise welding across various locations, including confined spaces and challenging environments. Its compact design ensures easy transport between workstations while maintaining professional performance.

● Advanced Ergonomic Design:

The ergonomic handle and balanced weight distribution reduce strain during extended use. Strategic control placement and cushioned grip minimize operator fatigue, ensuring consistent welding quality and high productivity throughout long work sessions.

● Streamlined Quick Setup:

The plug-and-play design with tool-free adjustments allows setup within minutes. This quick deployment is especially valuable in time-sensitive manufacturing where minimizing downtime is essential.

● Comprehensive Application Versatility:

This equipment works with a wide range of materials, from thermoplastics to specialized composites.

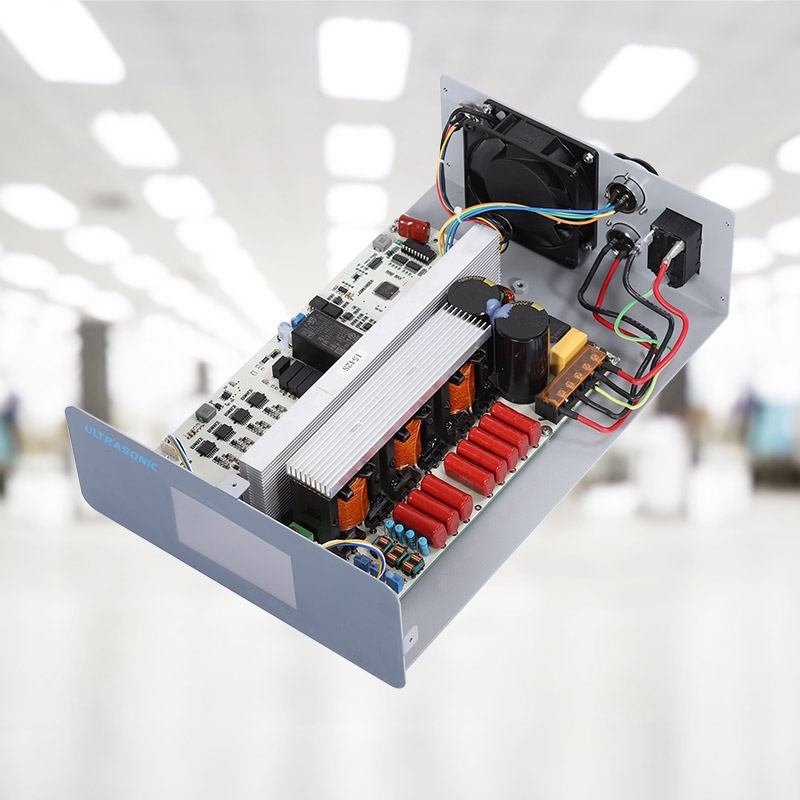

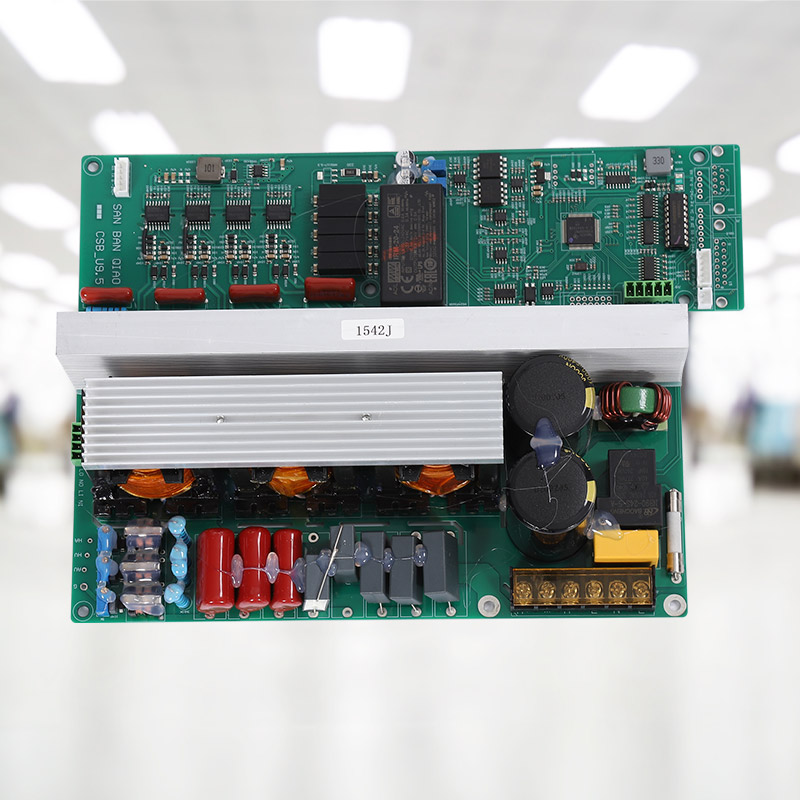

● Advanced Precision Control:

Digital controls enable fine adjustment of welding parameters - amplitude, pressure, and time. This precision ensures high-quality welds on plastic components while preserving structural integrity and appearance.

Request for Quote- Features |

- Parameters |

- Certification |

- Advantages |

- Packaging |

- Appilications |

- FAQs |

- Reviews

Handheld Ultrasonic Plastic Welder Features

Handheld portable ultrasonic spot welding machines are essential in modern welding technology, offering versatile and efficient applications.

These portable handheld ultrasonic spot welding machines serve multiple industries, including electronics, plastics, metals, apparel, footwear, crafts, and leather goods manufacturing. Specifically:

In electronics, they excel at welding battery components and circuit board connections with precision and efficiency. In plastics manufacturing, they perform precision assembly of parts, particularly welding and riveting thermoplastic products. In metalworking, while primarily used for miniature components, these portable machines are valuable for embedding and blanking processes between metal and plastic parts.

They've also transformed the apparel, footwear, crafts, and leather goods industries through spot welding, pressure welding, riveting, marking, and sealing. By replacing traditional joining methods like flux, adhesives, and rivets, these handheld portable ultrasonic plastic spot welding machines boost production efficiency and reduce costs.

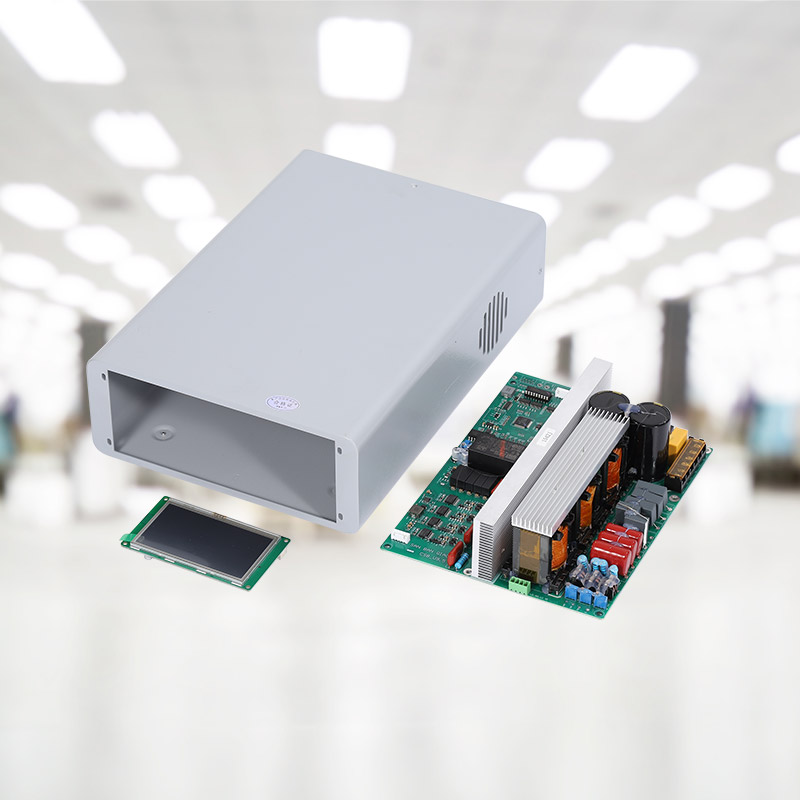

Handheld Ultrasonic Plastic Welder Parameters

| Parameters | ||

|---|---|---|

| Model | DZ-3521E | DZ-2808E |

| Frequency | 35KHZ | 28KHZ |

| Power | 1200W | 800W |

| Voltage | 220V | 220V |

| Amplitude Adjustment | 10%-100% accuracy adjustable, minimum adjustment accuracy 1% | 10%-100% accuracy adjustable, minimum adjustment accuracy 1% |

| Working Temperature | '-10℃ - 40℃ | '-10℃ - 40℃ |

| Weight | 10KGS | 10KGS |

| Size | 45 * 35 * 20CM | 45 * 35 * 20CM |

We are Internationally Certified

Our handheld portable ultrasonic spot welding machines are certificated with CE,ISO and ROSH. They all meet international standards.

Custom Dizo Handheld Portable Ultrasonic Spot Welding Machine Advantages

Handheld ultrasonic spot welding has several advantages as below.

-

High Efficiency

Ultrasonic spot welding needs no preheating, ensuring fast speeds suitable for mass production, thereby boosting efficiency.

-

Reliable and Stable

The ultrasonic spot welding process is highly controllable, resulting in strong welds and consistent product reliability.

-

Environmentally Friendly

It uses no adhesives or solvents, saves energy, and meets environmental standards.

-

Easy Operation

High automation makes it easy to operate and maintain, ideal for complex tasks and reducing labor costs.

Packaging for Handheld Ultrasonic Plastic Welder

Ultrasonic Welder for Different Industries

Ultrasonic welding is widely used in welding plastic products, including industries automotive, consumer electronics, medical, toys, packaging, and so on, especially where long-lasting, strong, and great-looking connections are needed.

FAQs

Here are frequently asked questions to consider before choosing an handheld portable ultrasonic spot welder for your plastic products.

Customer Reviews

Quote Now

Quote Now