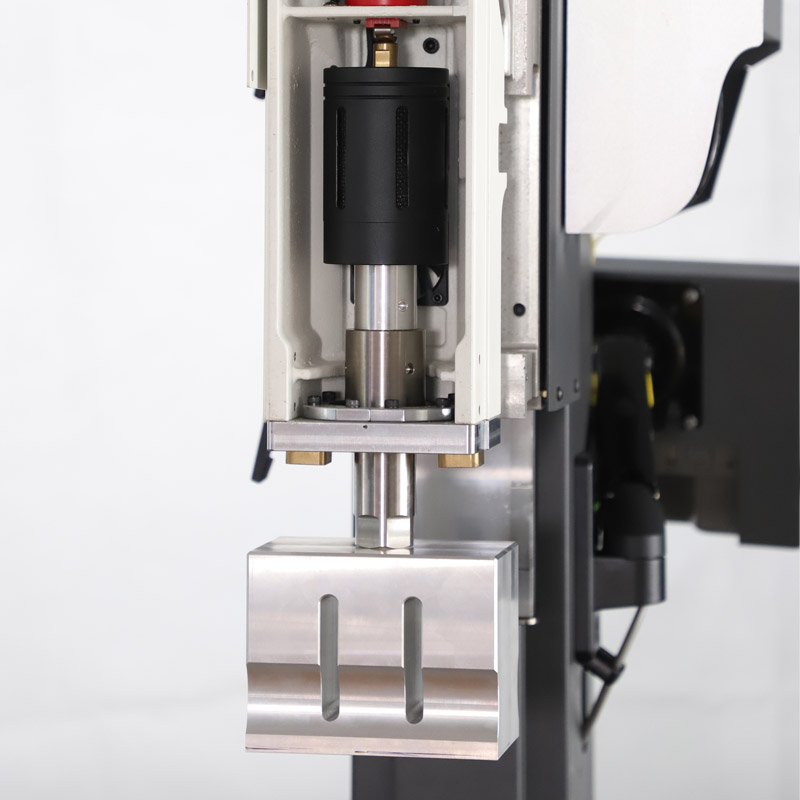

Servo Ultrasonic Welding Machine

20kHZ/35kHZ NC-F Ultrasonic Welder Series

● High-Precision Motor Control:

High-precision servo motors use advanced control algorithms to maintain height error tolerances of 0.05mm. This precision makes manufacturing products requiring the highest accuracy and consistency.

● Multi-Mode Control:

The multi-mode control system precisely manages depth, energy, and time parameters. This comprehensive approach improves welding precision and versatility, allowing the system to handle diverse manufacturing applications.

● Linear Guide Rail Design:

The linear guide rail system uses premium materials and precise machining to achieve 0.02mm repeatability accuracy. This stability ensures consistent quality and minimal variations during welding.

● Parameter Storage Function:

The system can store and instantly recall 999 welding parameter configurations. This feature streamlines production changes and maintains consistent quality across product lines, improving efficiency and reducing setup time.

● 485 Communication Design:

The RS-485 interface provides reliable connectivity with external automation systems and AI platforms. This enables smooth integration into smart manufacturing environments.

Request for Quote- Features |

- Parameters |

- Certification |

- Advantages |

- Packaging |

- Appilications |

- FAQs |

- Reviews

Servo Ultrasonic Welding Machine Features

Servo ultrasonic welding machines are essential in automotive manufacturing, delivering precise and efficient welding of components while ensuring secure bonds under high temperature and pressure conditions.

Servo ultrasonic welding machines excel in electronic component production, providing high-speed, precision welding that guarantees reliable performance. When welding housing products, sensors, switches, cables, and connectors, they maintain product integrity - leaving no scratches while fulfilling all sealing and functional requirements.

The medical device industry widely employs servo ultrasonic welding machines, as their precise and stable welding process makes them ideal for products demanding the highest standards of precision and hygiene.

With their combination of precise control, high efficiency, low energy consumption, and versatility across different materials and shapes, servo ultrasonic welding machines have become the industry's preferred welding solution.

Servo Ultrasonic Welder Parameters

| Parameters | ||

|---|---|---|

| Model | DZ-3512F | DZ-2020F |

| Frequency | 35KHZ | 20KHZ |

| Output Power | 1200W | 4000W |

| Sevo Motor Power | 400W | 400W |

| Voltage | 220V | 220V |

| Welding Time Accuracy | 0.01s | |

| Welding Adjusting Range | 0.01-9.99 sec | |

| Amplitude Control Range | ±25KHZ | |

| Weight | 150KGS | |

| Size | 70*50*140CM | |

We are Internationally Certified

Our digital servo ultrasonic welding machine are certificated with CE,ISO and ROSH. They all meet international standards.

Custom Servo Ultrasonic Welding Machine Advantages

Ultrasonic welding has several advantages as below.

-

High Efficiency

Ultrasonic welding needs no preheating, ensuring fast speeds suitable for mass production, thereby boosting efficiency.

-

Reliable and Stable

The ultrasonic welding process is highly controllable, resulting in strong welds and consistent product reliability.

-

Environmentally Friendly

It uses no adhesives or solvents, saves energy, and meets environmental standards.

-

Easy Operation

High automation makes it easy to operate and maintain, ideal for complex tasks and reducing labor costs.

Packaging for Servo Ultrasonic Welding Machine

Servo Ultrasonic Welding Machine for Different Industries

Digital servo ultrasonic welder is widely used in welding plastic products, including industries automotive, consumer electronics, medical, toys, packaging, and so on, especially where long-lasting, strong, and great-looking connections are needed.

FAQs

Here are frequently asked questions to consider before choosing an digital servo ultrasonic welding machine for your plastic products.

Customer Reviews

Quote Now

Quote Now