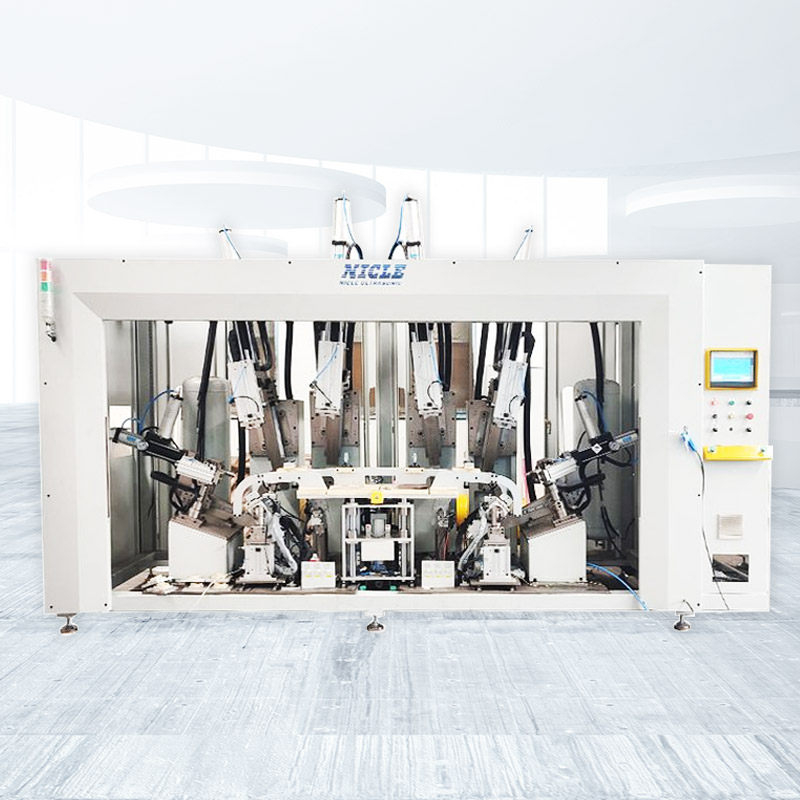

Car Door Panel Servo Heat Staking Machine

NC Series For Interior Components

● Adjustable Welding Units:

360-degree adjustable welding units feature independent parameter settings for precise heat staking operations.

● Independent System Structure:

Robust single-unit design maximizes reliability while minimizing maintenance requirements for car door panel heat staking.

● Head Angle Control:

Precise angle adjustments ensure optimal welding for all automotive door panel types.

● Workpiece Detection & Safety:

Integrated sensors monitor workpieces and automatically activate safety protocols when necessary.

● Fast and Efficient Welding:

High-speed performance delivers rapid processing while maintaining consistent quality in car door panel heat staking.

● Conclusion:

Hot staking welding technology for automotive door panel plastics works with various materials—including polyethylene, polypropylene, and polyvinyl chloride. The process offers high welding strength, superior sealing performance, rapid processing speeds, and significant potential for optimization.

Request for Quote- Features |

- Certification |

- Copperation Steps |

- Advantages |

- Packaging |

- Technology |

- Appilications |

- Reviews

Car Door Panel Servo Heat Staking Machine Features

Heat staking welding plays a vital role in automotive plastic door panel manufacturing. This technique has become essential in the industry due to its ability to effectively process various materials like ABS, PP, PE, and other plastics commonly used in car door panels.

The heat staking welding process creates exceptionally strong bonds by fusing two plastic parts into a single unit. The resulting welded joint often surpasses the strength of the original materials, ensuring car door panels that are both stable and durable. When the plastic surfaces melt and join, they form a tight seal that effectively blocks water, dust, and other contaminants from entering the vehicle. This sealing capability is essential for maintaining a clean, comfortable vehicle interior.

The heat staking welding technology seamlessly integrates with modern high-speed assembly lines. Its rapid welding speed boosts production efficiency while reducing costs—a critical advantage in the competitive automotive manufacturing sector. As an added benefit, hot melt welding is environmentally responsible. The process emits no harmful gases, and the adhesive contains 100% solid content. Non-toxic, and free from secondary environmental impacts.

We are Internationally Certified

Our car door panel heat Staking machines are certificated with CE,ISO and ROSH. They all meet international standards.

Purchasing Guide: Car Door Panel Heat Staking Machines

We provide comprehensive plastic welding solutions for automotive door panel plastic parts. Follow these steps to complete the process:

-

STEP 1

Sample Evaluation

Review automotive door panel sample requirements and technical specifications.

-

STEP 2

Feasibility Study

Analyze the feasibility of the welding techniques for the automotive door panel application.

-

STEP 3

Prototype Development

Create and test prototypes based on the evaluated automotive door panel samples.

-

STEP 4

Customer Approval

Present the prototype to gather feedback and secure customer approval.

-

STEP 5

Quotation

Issue a detailed quotation for the selected heat Staking machine.

-

STEP 6

Order Confirmation

Finalize the order and confirm all specifications.

-

STEP 7

Manufacturing Process

Manufacture the heat Staking machine according to the confirmed order details.

-

STEP 8

Quality Assurance

Conduct thorough quality checks to ensure the machine meets all standards.

-

STEP 9

Delivery and Installation

Deliver the welding machine and complete installation at the customer's site.

-

STEP 10

Training and Support

Provide training and ongoing support to ensure smooth operation of the equipment.

Custom Dizo Automotive Door Panel Servo Heat Staking Machine Advantages

Custom Solution

Solutions customized to your specific needs, supported by 21 engineers ready to assist anytime.

Save Your Time

Full project oversight from initial requirements to final delivery, ensuring efficiency and time savings.

Guaranteed Quality Assurance

Adheres to ISO standards for consistent and reliable quality throughout the process.

Professional Service Team

A professional 20-person service team ensures seamless hot staking welder installation and complete customer satisfaction.

Packaging for Car Door Panel Servo Heat Staking Machine

Plastic Welding Techniques in the Automotive Industry

Different welding applications demand specific approaches. Automotive companies often require a blend of ultrasonic welding systems, hot staking welders, vibration welding machines, and hybrid solutions.

We specialize in integrating automated plastic hot staking welding into automotive assembly lines, enhancing both efficiency and product quality.

Custom-designed plastic welding mold and precise positioning allow us to tackle complex tasks, such as welding large instrument clusters, resulting in superior surface finishes and precise gap control.

Ask for Quote Now

Other Automotive Plastic Components Welding Applications

We provide specialized plastic welding solutions for automotive components that meet all production requirements.

Customer Reviews

Quote Now

Quote Now