Understanding Ultrasonic Sewing Machines

An ultrasonic sewing machine is a modern machine that uses high-frequency vibrations to bond fabrics together. Unlike traditional sewing machines, it doesn't rely on needles and thread to create seams and hems. Instead, it works by transmitting ultrasonic waves through the fabric to create heat and melt the material, fusing it together. This process is faster and more efficient than traditional sewing methods, making it ideal for use in industrial settings.

How Ultrasonic Sewing Machines Work

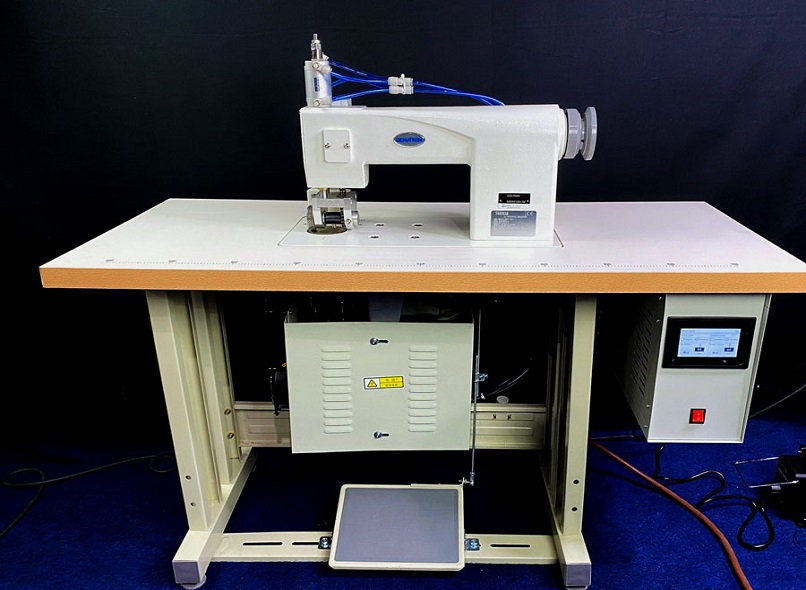

An ultrasonic sewing machine consists of a generator, a transducer, and a horn. The generator produces high-frequency electrical energy, which is transmitted to the transducer. The transducer then converts this electrical energy into mechanical vibrations, which are amplified by the horn.

When the horn comes into contact with the fabric, the vibrations create friction and generate heat. This heat melts the fabric, causing it to bond together. The process is very fast, with each bond taking only a fraction of a second.

One of the benefits of using an ultrasonic sewing machine is that it doesn't require a lot of pressure to create the bond. This means that delicate fabrics can be bonded without the risk of damage or distortion. Additionally, the heat is confined to a small area, so the surrounding fabric is not affected.

Advantages of Ultrasonic Sewing Machines

Ultrasonic sewing machines offer several advantages over traditional sewing methods. They are faster, require no thread, and can bond a wide range of materials, including synthetic fabrics, nonwovens, and films. This makes them ideal for use in industries such as automotive, medical, and filtration, where a variety of materials may need to be bonded together.

Another benefit of using ultrasonic sewing machines is that they create a strong bond that is resistant to tearing and fraying. This makes them ideal for use in applications where durability is important. Finally, ultrasonic sewing machines are easy to operate and require minimal training, making them a good choice for workers of all skill levels.

Ultrasonic sewing machines are an innovative and efficient alternative to traditional sewing methods. They offer faster production times, require no thread, and can bond a wide range of materials. Whether you work in the automotive, medical, or filtration industry, an ultrasonic sewing machine can help you create high-quality, durable products that meet your customers' needs.