How Ultrasonic Generators Work

Ultrasonic welding generators are versatile tools used in many applications, including cleaning, welding, and medical procedures. These generators produce high-frequency vibrations essential for many industrial processes. But how do they work? In this article, we'll explore the science behind ultrasonic welding generators and their inner workings.

Ultrasonic Vibration

Before we dive into the details of ultrasonic welding generators, let's understand what ultrasonic vibration is. Ultrasonic vibration is a type of mechanical vibration that occurs at a frequency higher than the human ear can hear, typically above 20 kHz. This high-frequency vibration is produced by an ultrasonic welding generator, which converts electrical energy into mechanical energy.

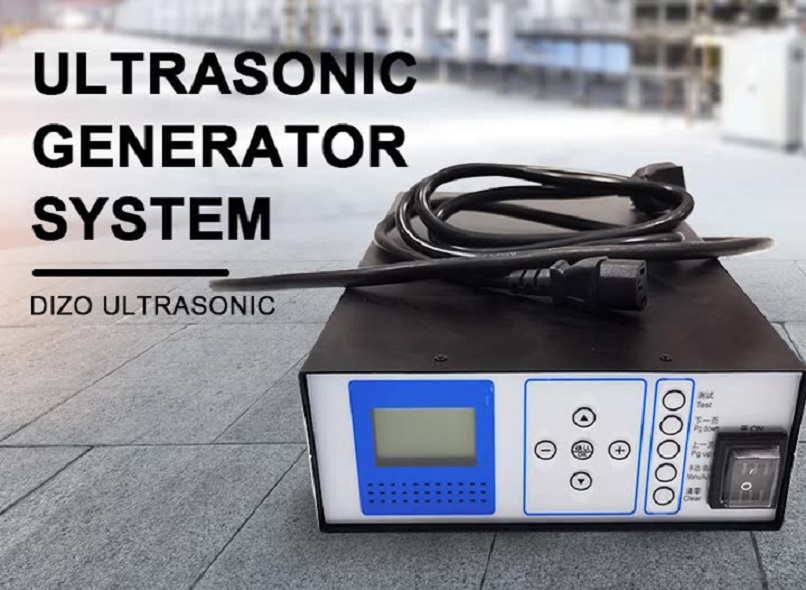

Components of an Ultrasonic Generator

The ultrasonic welding generator is made up of three main components: a power supply, a transducer, and a booster.

The Transducer

The transducer is the heart of the ultrasonic generator. It contains a stack of piezoelectric crystals that convert electrical energy into mechanical energy. When an electrical current flows through the crystals, they vibrate at a high frequency, producing ultrasonic waves. The ultrasonic wave frequency depends on the thickness of the crystal and the frequency of the electrical signal.

The Booster

The booster is a mechanical device that amplifies the vibration produced by the transducer and transfers it to the working tool or surface. It is typically made of a metal alloy such as titanium or aluminum, which has a high acoustic conductivity. The booster is designed to match the frequency of the transducer and maximize the transfer of energy.

The Power Supply

The power supply provides the electrical energy needed to drive the transducer. It consists of a high-frequency generator, a transformer, and a control circuit. The high-frequency generator produces an electrical signal at the desired frequency, which is then amplified by the transformer and applied to the transducer.

Applications of Ultrasonic Generators

Ultrasonic welding generators are used in a variety of applications, including:

- Cleaning: Ultrasonic waves can clean surfaces, equipment, and parts. The high-frequency vibration creates tiny bubbles in a cleaning solution, which implode and remove dirt and grime.

- Welding: Ultrasonic welding uses high-frequency vibrations to join two materials together. The materials are placed under pressure and subjected to ultrasonic vibrations, which create heat and melt the materials together.

- Medical Procedures: Ultrasonic waves are used in medical procedures such as imaging, surgery, and therapy. Ultrasonic imaging uses high-frequency sound waves to create images of internal organs and tissues. Ultrasonic surgery uses high-energy ultrasonic waves to cut and coagulate tissue. Ultrasonic therapy uses low-frequency ultrasonic waves to stimulate tissue healing and reduce pain.

Ultrasonic welding generators are powerful tools that convert electrical energy into high-frequency mechanical vibrations used in various applications. By understanding their inner workings, we can appreciate the science behind these remarkable devices.