Hot-plate welding PMMA with PVC

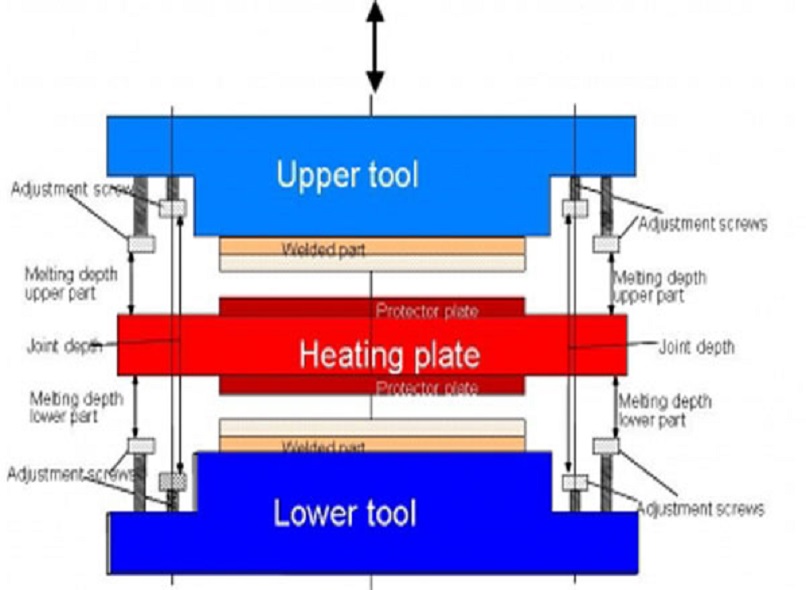

In today's rapidly evolving manufacturing industry, hot-plate welding has emerged as a popular technique for joining thermoplastic materials. In this article, we will explore the process of hot-plate welding PMMA (Polymethyl Methacrylate) with PVC (Polyvinyl Chloride), two widely used thermoplastics. By understanding the effects of welding parameters, optimizing the process, and exploring the latest advancements in hot-plate welding techniques, we can enhance the quality, strength, and durability of the joints between PMMA and PVC.

1. Exploring the Effects of Hot-Plate Welding Parameters on the Bond Strength of PMMA with PVC

The bond strength of a hot-plate welded joint between PMMA and PVC is influenced by various welding parameters. Temperature, pressure, heating time, and cooling time are critical factors that impact the quality and strength of the joint. In this section, we will delve into the effects of these parameters on the bond strength, analyzing their individual and combined influence on the welding process. By understanding the optimal ranges for these parameters, manufacturers can achieve stronger and more durable joints between PMMA and PVC.

2. Investigating the Microstructural Changes in PMMA-PVC Joints Fabricated by Hot-Plate Welding

Hot-plate welding induces microstructural changes at the interface between PMMA and PVC. In this section, we will examine the microstructure of hot-plate welded joints at a microscopic level. By analyzing the bonding mechanisms, interfacial morphology, and molecular interactions, we can gain insights into the strength and integrity of the joint. Understanding the microstructural changes is crucial for identifying any potential weaknesses, defects, or stress concentration zones that may affect the long-term performance of the joint.

3. Enhancing the Joint Quality of PMMA-PVC Assemblies through Optimization of Hot-Plate Welding Process

To achieve high-quality joints between PMMA and PVC, it is essential to optimize the hot-plate welding process. This section will focus on various aspects of process optimization, including surface preparation techniques, selection of welding parameters, precision control of temperature and pressure, and optimization of heating and cooling cycles. By implementing these optimization strategies, manufacturers can improve the joint quality, strength, and overall performance of PMMA-PVC assemblies.

4. Evaluating the Thermal and Mechanical Properties of Hot-Plate Welded PMMA-PVC Structures

The thermal and mechanical properties of hot-plate welded PMMA-PVC structures play a crucial role in determining their suitability for specific applications. In this section, we will evaluate the strength, stiffness, impact resistance, thermal stability, and other relevant properties of the welded joints. By conducting thorough testing and analysis, we can assess the performance of the joints under different environmental conditions and mechanical loads. This evaluation will help manufacturers determine the applicability of hot-plate welded PMMA-PVC structures in various industries, such as automotive, construction, and electronics.

5. Advancements in Hot-Plate Welding Techniques for Joining PMMA and PVC Materials

The field of hot-plate welding is constantly evolving, with continuous advancements in techniques and equipment. In this final section, we will explore the latest innovations in hot-plate welding techniques for joining PMMA and PVC materials. These advancements may include the development of new heating systems, improvements in temperature and pressure control, integration of automation and robotics, and the use of advanced monitoring and control systems. By staying updated with these advancements, manufacturers can leverage cutting-edge technologies to enhance the efficiency, precision, and reliability of the hot-plate welding process for PMMA-PVC joints.

Conclusion

Hot-plate welding offers a robust and efficient method for joining PMMA with PVC, two commonly used thermoplastic materials. By understanding the effects of welding parameters, optimizing the process, and embracing the latest advancements in hot-plate welding techniques, manufacturers can achieve superior joint quality, strength, and durability. With optimized hot-plate welding processes, manufacturers can confidently utilize PMMA-PVC joints in a wide range of applications, contributing to the advancement and success of various industries.