Unlocking the Potential: Exploring the Intricacies of an Ultrasonic Welding Generator Circuit

Ultrasonic welding has emerged as a highly efficient and precise method for joining materials in the manufacturing industry. At the heart of this cutting-edge welding process lies the ultrasonic welding generator circuit, a complex system that generates the electrical signals necessary to produce the high-frequency vibrations. In this comprehensive article, we will delve into the intricacies of an ultrasonic welding generator circuit, exploring its components, functions, and the advancements that drive its evolution.

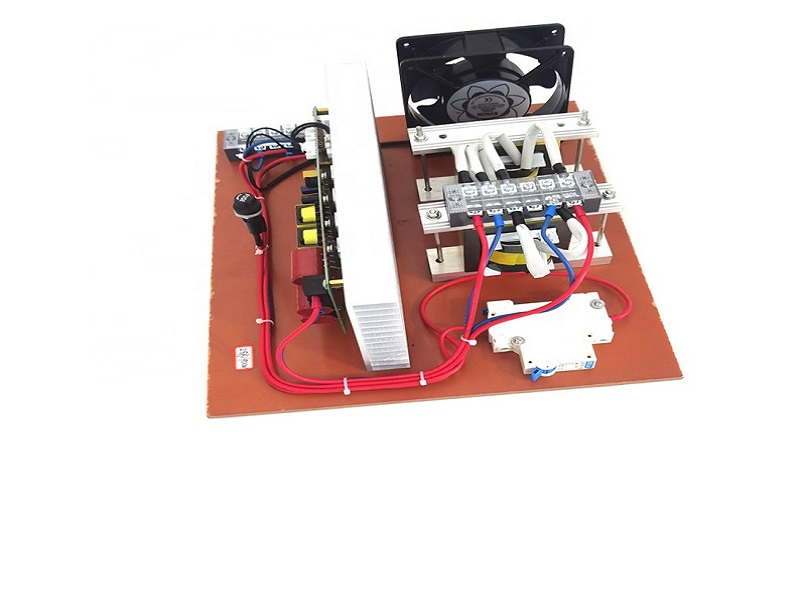

Unveiling the Components of an Ultrasonic Welding Generator Circuit

The ultrasonic welding generator circuit is a sophisticated assembly of components that work in harmony to enable the welding process. At its core is the power supply, which provides a steady and reliable source of electrical power to the circuit. This power supply can be either a direct current (DC) source or an alternating current (AC) source, depending on the specific requirements of the welding application.

One of the key components of the generator circuit is the frequency generator. This generator is responsible for producing the high-frequency electrical signals required for ultrasonic welding. The frequency of these signals typically ranges from 15 kHz to 70 kHz, depending on the materials being welded and the desired welding strength. The frequency generator ensures that the vibrations are finely tuned to achieve optimal welding results.

To amplify the generated signals, the circuit incorporates an amplifier. The amplifier increases the power of the signals to a level suitable for driving the transducer. This amplification process ensures that the mechanical vibrations produced by the transducer are strong enough to facilitate the bonding of materials.

The transducer is a crucial component that converts the electrical signals into mechanical vibrations. It typically consists of piezoelectric crystals or ceramics that change shape when subjected to an electric field. These shape changes create the mechanical vibrations necessary for welding.

Another essential component of the ultrasonic welding generator circuit is the matching network. This network ensures that the generated signals are efficiently transferred from the generator to the transducer. It helps to minimize signal loss and maximize the energy transfer, resulting in effective and reliable welding performance.

The Significance of a Well-Designed Ultrasonic Welding Generator Circuit

A well-designed ultrasonic welding generator circuit diagram is indispensable for understanding the intricate workings of the welding process. It provides a visual representation of the circuit components and their interconnections, allowing operators and technicians to comprehend the system's functionality and troubleshoot potential issues efficiently. A comprehensive circuit diagram ensures that operators can identify and rectify faults promptly, minimizing downtime and maximizing productivity.

Advancements Driving Ultrasonic Welding Generator Circuit Technology

Advancements in technology continue to drive the evolution of ultrasonic welding generator circuits, enabling improved performance and enhanced functionality. Modern circuits incorporate advanced control systems, digital interfaces, and intelligent power management techniques. These advancements enhance the precision, reliability, and efficiency of the welding process, resulting in higher quality welds, increased production rates, and improved overall performance. Additionally, the integration of advanced sensing technologies and feedback mechanisms enables real-time monitoring and adaptive control, further optimizing the welding process.

Pioneering the Future of Ultrasonic Welding Generator Circuits

As technology continues to advance at a rapid pace, the future of ultrasonic welding generator circuits holds tremendous potential. Ongoing research and development efforts focus on refining control algorithms, exploring new materials for transducers, and harnessing the potential of emerging technologies such as artificial intelligence and machine learning. These advancements aim to achieve even greater precision, energy efficiency, and versatility in ultrasonic welding, expanding its applications across diverse industries and driving innovation in manufacturing processes.

Moreover, the incorporation of advanced connectivity features and cloud-based systems opens up new possibilities for remote monitoring, data analysis, and predictive maintenance of ultrasonic welding generator circuits. This level of connectivity enables manufacturers to optimize their welding processes, reduce downtime, and enhance overall operational efficiency.

In conclusion, the ultrasonic welding generator circuit is a critical component in understanding the inner workings of the ultrasonic welding process. It provides the necessary electrical signals to generate mechanical vibrations that facilitate the joining of materials. With advancements in technology, ultrasonic welding generator circuits are poised to become even more sophisticated, enabling precise control, improved performance, and transformative advancements in the manufacturing industry. The future of ultrasonic welding generator circuits is bright, promising enhanced productivity, efficiency, and innovation in the world of manufacturing. By unlocking the full potential of the ultrasonic welding process, these circuits are set to revolutionize the way materials are joined, driving progress and shaping the future of manufacturing.

See more ultrasonic plastic welders