Custom Rotary Table Ultrasonic Welding Machines Services: Precision, Efficiency, and Quality

Ultrasonic welding is a reliable and efficient way to join thermoplastic materials that has become indispensable in various industries. When it comes to high-precision and high-throughput ultrasonic welding, custom rotary table ultrasonic welding machines are game-changers. These machines offer precision, efficiency, and quality, making them essential for businesses looking to improve their manufacturing processes. In this article, we will explore custom rotary table ultrasonic welding machines and the services they offer, highlighting their advantages and applications.

The Basics of Ultrasonic Welding

Before we delve into the specifics of custom rotary table ultrasonic welding machines, let's briefly review the fundamentals of ultrasonic welding. Ultrasonic welding is a solid-state welding process that uses high-frequency ultrasonic vibrations to create heat through friction at the joint interface of two materials. This localized melting and subsequent bonding of the materials result in a strong and reliable weld. Ultrasonic welding is widely used in industries such as automotive, medical, electronics, packaging, and more, where precision and speed are crucial.

The Role of Rotary Tables

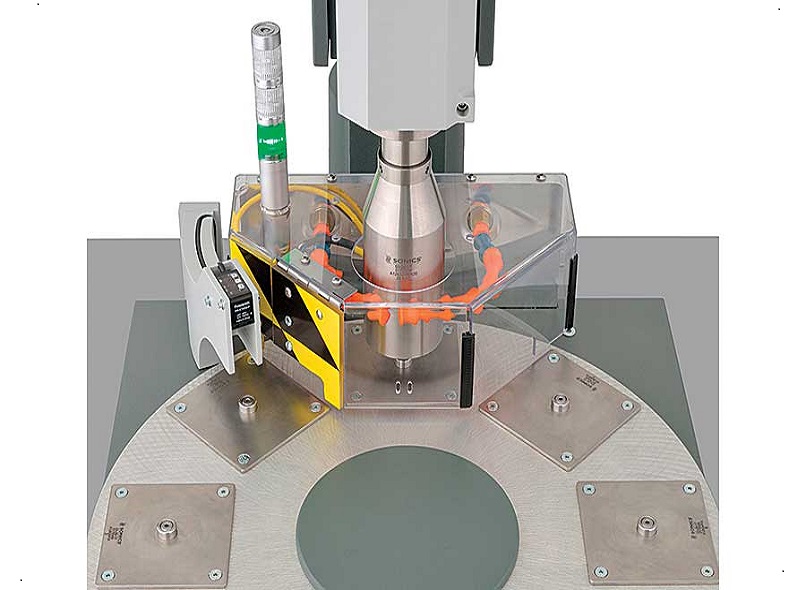

Custom rotary tables enhance the efficiency of rotary table ultrasonic welding processes by providing a platform for parts to rotate during welding. This rotation allows for uniform and consistent welding of multiple parts, reducing cycle times and increasing production output. Rotary tables are particularly beneficial for applications involving intricate designs, multiple weld points, and high-volume production.

Customization in Ultrasonic Welding Machines

Customization is the key to optimizing ultrasonic welding processes for specific applications. When it comes to custom rotary table ultrasonic welding machines, extensive customization is available. Here are some aspects that can be tailored to meet the unique needs of different industries:

1. Table Size and Configuration

Custom rotary tables can be designed in various sizes and configurations to accommodate different part sizes and geometries. Whether you are welding small components or large assemblies, a custom rotary table can be engineered to fit your requirements precisely.

2. Ultrasonic Welding Parameters

The rotary table ultrasonic welding machine parameters, including frequency, amplitude, and welding time, can be fine-tuned to ensure optimal weld quality and consistency. Custom machines allow for easy adjustments to meet specific material and part specifications.

3. Automation Integration

For seamless integration into an automated production line, custom rotary table ultrasonic welding machines can be equipped with robotics, vision systems, and conveyor systems. This automation not only improves efficiency but also reduces labor costs.

4. Tooling and Fixture Design

Custom fixtures and tooling are essential for holding parts securely during the welding process. These fixtures can be designed to match the exact shape and size of the parts being welded, ensuring precise alignment and consistent weld quality.

5. Material Compatibility

Different materials require different rotary table ultrasonic welding machine techniques. Custom ultrasonic welding machines can be optimized for specific thermoplastic materials, including those with unique properties or additives.

Advantages of Custom Rotary Table Ultrasonic Welding Machines

Investing in custom rotary table ultrasonic welding machines offers several distinct advantages for businesses in various industries:

1. Enhanced Precision

Custom machines can achieve the highest levels of precision, ensuring that each weld is consistent and of the highest quality. This is especially critical for industries like medical device manufacturing, where precision is non-negotiable.

2. Increased Efficiency

The integration of a rotary table significantly reduces cycle times by allowing multiple parts to be welded simultaneously. This leads to higher production output without compromising on weld quality.

3. Improved Quality Control

Custom machines often come equipped with advanced monitoring and quality control systems. These systems can detect and rectify issues in real-time, reducing the likelihood of defects and ensuring that only high-quality products leave the production line.

4. Cost Savings

While the initial investment in custom rotary table ultrasonic welding machine may be higher, the long-term cost savings are substantial. Reduced labor costs, higher throughput, and lower defect rates all contribute to a positive return on investment.

5. Versatility

Custom machines can be adapted for various applications within the same facility, making them versatile assets. They can accommodate changes in production requirements and expand the range of products a company can manufacture.

Applications of Custom Rotary Table Ultrasonic Welding Machines

Custom rotary table ultrasonic welding machines find applications in a wide range of industries due to their versatility and precision. Some notable industries where these machines are indispensable include:

1. Automotive

In the automotive industry, custom rotary table ultrasonic welding machines are used for welding components such as interior trim panels, dashboard assemblies, and air ducts. Their speed and precision contribute to the production of high-quality vehicles.

2. Medical Devices

Manufacturers of medical devices rely on custom rotary table ultrasonic welding machine to create hermetically sealed enclosures for electronic components, as well as to weld tubing for fluid and gas handling. The precise and contamination-free welds are essential for patient safety.

3. Electronics

Custom machines play a vital role in the production of electronic devices, including the assembly of sensors, connectors, and housings. Their ability to handle delicate components and provide a clean welding process is crucial in this industry.

4. Packaging

In the packaging industry, custom rotary table ultrasonic welding machines are used to create secure seals on blister packs, clamshells, and other packaging materials. The airtight seals ensure product freshness and integrity.

5. Consumer Goods

Manufacturers of consumer goods such as toys, appliances, and household products benefit from custom rotary table ultrasonic welding machine to assemble various components with precision and speed.

Custom rotary table ultrasonic welding machines have revolutionized the way industries approach the assembly and production of thermoplastic components. Their precision, efficiency, and versatility make them an invaluable asset for companies looking to improve their manufacturing processes. Whether you are in the automotive, medical, electronics, packaging, or consumer goods industry, the advantages of investing in custom ultrasonic welding machines are clear: improved product quality, increased production efficiency, and long-term cost savings. As technology continues to advance, custom solutions will only become more essential in meeting the unique demands of each industry, ensuring that the products we use and rely on every day are of the highest quality.