What is the process of vibration welding, and what is the cycle time for vibration welding?

Vibration welding is a widely used joining process in industries that deal with thermoplastic materials. It is a technique that utilizes frictional heat generated by the rapid oscillation of two mating surfaces under pressure. This process is highly effective in creating strong and durable bonds between thermoplastic parts.

The process of vibration welding involves several important steps. Firstly, the surfaces to be joined must be prepared thoroughly. This typically involves cleaning the surfaces and removing any contaminants that could hinder the vibration welding process. Additionally, surface treatments such as applying adhesives or using primers may be necessary to enhance the adhesion between the mating surfaces.

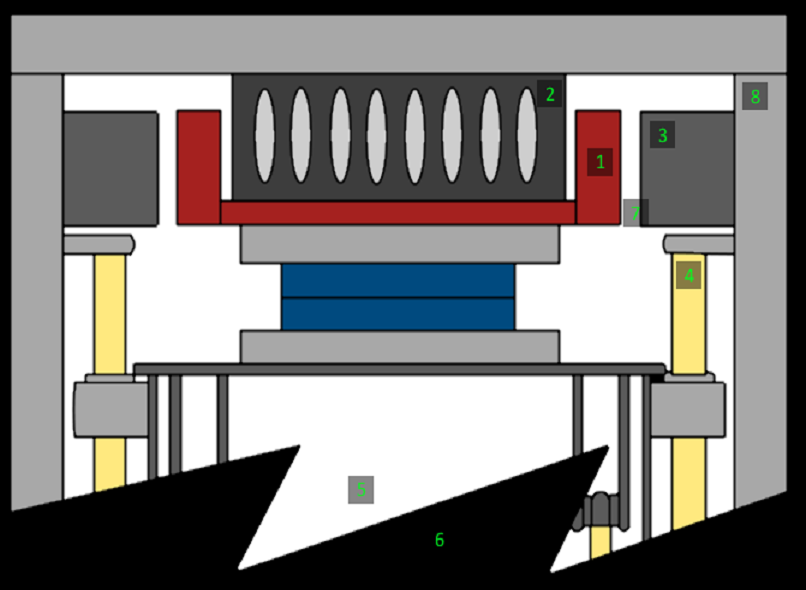

Once the surfaces are prepared, the actual welding process begins. The two parts to be joined are brought together under pressure, with one part oscillating relative to the other. The oscillation creates frictional heat, which softens the material and facilitates the vibration welding process. The frequency and amplitude of the oscillation are carefully controlled to ensure optimal heat generation and material flow.

During the vibration welding process, the softened material starts to fuse together as a result of the pressure applied. The continuous oscillation ensures that the heat and pressure are evenly distributed, resulting in a strong and uniform weld. It is worth noting that the oscillation frequency and amplitude can be adjusted depending on the specific requirements of the welding application.

Now, let's talk about the cycle time for vibration welding. The cycle time refers to the total time required to complete one welding cycle, including the preparation, assembly, and welding stages. The cycle time can vary depending on several factors, such as the type of thermoplastic material being welded, the size and complexity of the parts, and the desired strength of the weld.

In general, cycle times for vibration welding can range from a few seconds to a few minutes. However, it is important to optimize the cycle time to ensure efficient production while maintaining the desired quality of the weld. Factors such as the material's melting and cooling characteristics, the machine's capabilities, and the desired production volume should be considered when determining the optimal cycle time.

In conclusion, vibration welding is a versatile and efficient joining process for thermoplastic materials. By harnessing frictional heat generated through oscillation, this technique creates strong and reliable bonds. The cycle time for vibration welding can vary depending on various factors, and it is crucial to find the right balance between production efficiency and weld quality.