Manual Ultrasonic Welding Machine

15kHZ/20kHZ NC-E Ultrasonic Welder Series

● Human-Machine Interface:

The full-touch interface offers easy operation with real-time monitoring and simple maintenance. The high-resolution display shows all operational parameters and system status clearly.

● Traceability Design:

The system automatically records welding parameters—temperature, pressure, and duration. This data logging improves quality control, boosts reliability, and reduces waste by catching potential issues early.

● Tracking Frequency Control:

Millisecond-level frequency tracking maintains stable output through continuous monitoring. This precise control ensures consistent welding quality by adjusting for material and environmental variations.

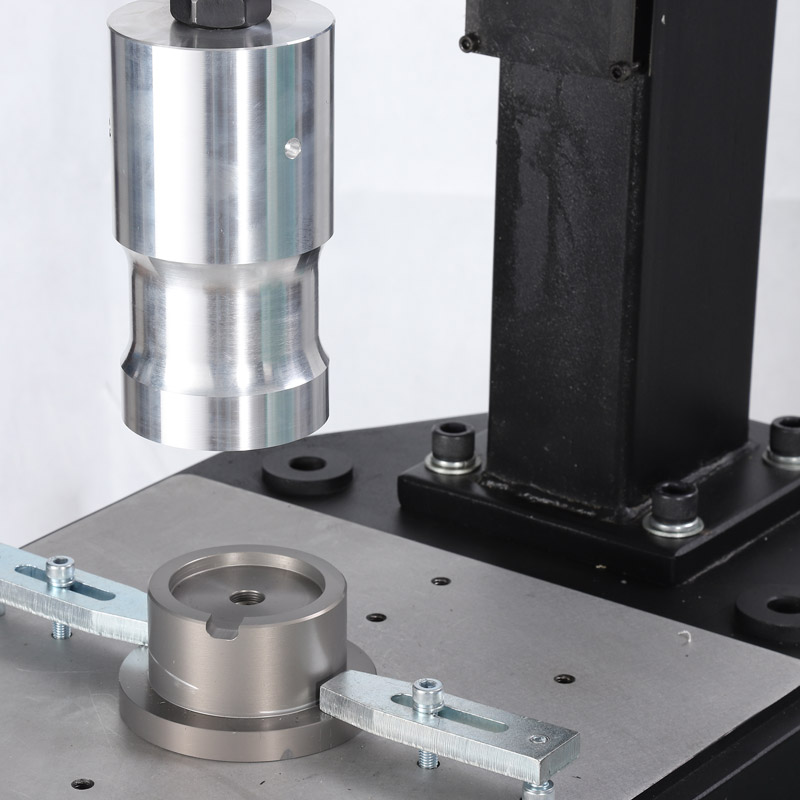

● CNC Processing and Casting:

High-quality CNC machining and heavy-duty casting provide excellent structural integrity and stability. Precision-engineered parts ensure accurate positioning, while the robust frame reduces vibration.

● Square Column Design:

The square column structure features reinforced supports to prevent tilting during large-scale welding. This stability allows the ultrasonic welding machine to handle various product sizes while maintaining precise welds.

Request for Quote- Features |

- Parameters |

- Certification |

- Advantages |

- Packaging |

- Appilications |

- FAQs |

- Reviews

Manual Ultrasonic Welding Machine Features

Manual ultrasonic welding machines play a vital role in automotive parts manufacturing, joining plastic components with exceptional precision and reliability. The resulting welds combine outstanding strength with exact dimensional accuracy - qualities essential for critical automotive applications.

These manual ultrasonic welding machines have revolutionized plastic electronics manufacturing. They excel at complex assembly tasks, from joining smartphone and tablet casings to encapsulating sensitive electronic components. Their ability to create strong, clean bonds without harming delicate electronics has made them indispensable in modern electronics production.

The ultrasonic welding technology's reach extends across numerous industries. It creates durable, child-safe products in toy and stationery manufacturing, while enabling precise welding of surgical instruments and medical vessels under rigorous quality controls.

The manual ultrasonic welders also shine in household product manufacturing, effectively joining materials for sealed containers and food storage. They even master challenging materials like non-woven fabrics and leather, surpassing traditional joining methods.

Manual Ultrasonic Welder Parameters

| Parameters | ||||

|---|---|---|---|---|

| Model | DZ-1526E | DZ-2020E | DZ-1532E | DZ-3521E |

| Frequency | 15KHZ | 20KHZ | 15KHZ | 15KHZ |

| Power | 2600W | 2000W | 3200W | 1200W |

| Voltage | 220V | 220V | 220V | 220V |

| Amplitude Adjustment | 10%-100% accuracy adjustable,minimum adjustment accuracy 1% | 10%-100% accuracy adjustable,minimum adjustment accuracy 1% | ||

| Working Temperature | -10℃ - 40℃ | -10℃ - 40℃ | ||

| Weight | 120KGS | 120KGS | 300KGS | 120KGS |

| Size | 70*80*130CM | 70*80*130CM | 80*90*220CM | 70 * 80 * 130CM |

We are Internationally Certified

Our manual ultrasonic welding machines are certificated with CE,ISO and ROSH. They all meet international standards.

Custom Dizo Manual Ultrasonic Welding Machine Advantages

Ultrasonic welding has several advantages as below.

-

High Efficiency

Ultrasonic welding needs no preheating, ensuring fast speeds suitable for mass production, thereby boosting efficiency.

-

Reliable and Stable

The process is highly controllable, resulting in strong welds and consistent product reliability.

-

Environmentally Friendly

It uses no adhesives or solvents, saves energy, and meets environmental standards.

-

Easy Operation

High automation makes it easy to operate and maintain, ideal for complex tasks and reducing labor costs.

Packaging for Manual Ultrasonic Welding Machine

Manual Ultrasonic Welding Machine for Different Industries

Ultrasonic welder is widely used in welding plastic products, including industries automotive, consumer electronics, medical, toys, packaging, and so on, especially where long-lasting, strong, and great-looking connections are needed.

FAQs

Here are frequently asked questions to consider before choosing an manual ultrasonic welding machine for your plastic products.

Customer Reviews

Quote Now

Quote Now