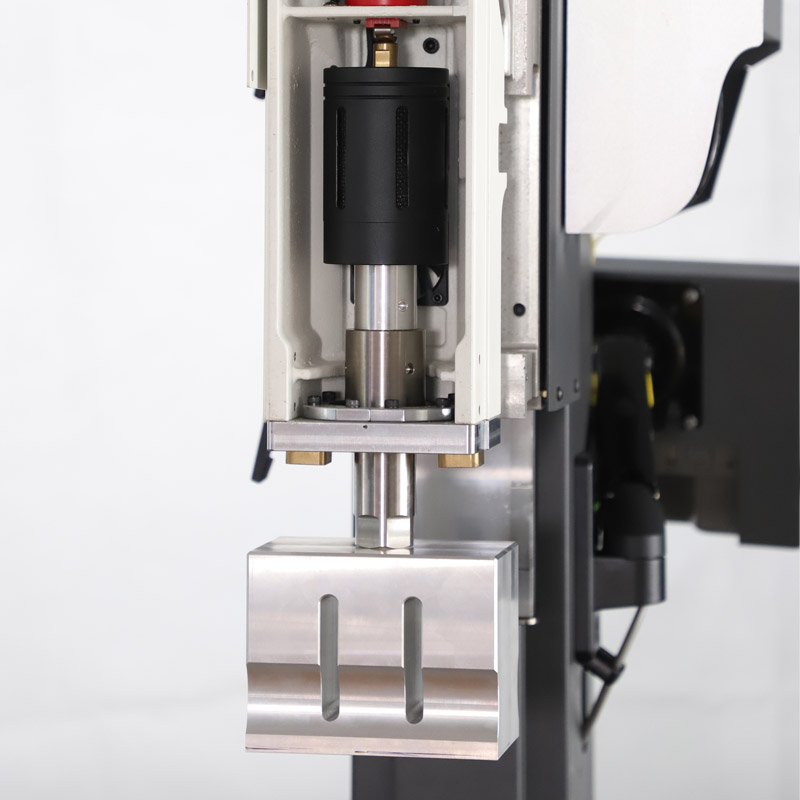

Servo Ultrasonic Welder Manufacturer

20kHZ/35kHZ NC-F Series

● High-Precision Motor Control:

The high-precision servo motors maintain height error within 0.05mm, ensuring suitability for high-precision product manufacturing.

● Multi-Mode Control:

The multi-mode control of depth, energy, and time enhances welding precision, allowing for a broader range of product applications.

● Linear Guide Rail Design:

The linear guide rail design achieves a repeatability accuracy of 0.02mm, stabilizing the welding process.

● Parameter Storage Function:

The storage of 999 welding parameters simplifies product changes, ensuring convenience.

● 485 Communication Design:

The 485 communication design enables seamless integration with external automation or AI, facilitating automated production.

Request for Quote- Features |

- Parameters |

- Advantages |

- Packaging |

- Appilications |

- FAQs |

- Certification |

- Reviews

Features

These ultrasonic plastic welders feature a state-of-the-art servo control system that ensures high precision and consistent welding results, making them a top choice for manufacturers. Operating at frequencies of 20 kHz, and 35 kHz, they are among the most advanced ultrasonic welding machines available in China today.

Dizo offers a variety of ultrasonic welders for sale that cater to diverse applications, ensuring that you find the right ultrasonic plastic welding machine for your needs. These machines are designed to improve efficiency and reduce production costs, while also maintaining quality.

As leading plastic welding equipment, they are crafted to provide strong, reliable welds essential for various industries. By sourcing from reputable ultrasonic welding machine suppliers, Dizo guarantees high-quality products that meet rigorous industry standards.

Whether you are looking to upgrade your current setup or invest in new technology, these ultrasonic welders represent an excellent choice for enhancing your production capabilities and achieving superior welding performance.

Parameters

| Parameters | ||

|---|---|---|

| Model | DZ-3512F | DZ-2020F |

| Frequency | 35KHZ | 20KHZ |

| Output Power | 1200W | 4000W |

| Sevo Motor Power | 400W | 400W |

| Voltage | 220V | 220V |

| Welding Time Accuracy | 0.01s | |

| Welding Adjusting Range | 0.01-9.99 sec | |

| Amplitude Control Range | ±25KHZ | |

| Weight | 150KGS | |

| Size | 70*50*140CM | |

Benefits of Ultrasonic Welding

Ultrasonic welding has several advantages as below.

-

High Efficiency

Ultrasonic welding needs no preheating, ensuring fast speeds suitable for mass production, thereby boosting efficiency.

-

Reliable and Stable

The process is highly controllable, resulting in strong welds and consistent product reliability.

-

Environmentally Friendly

It uses no adhesives or solvents, saves energy, and meets environmental standards.

-

Easy Operation

High automation makes it easy to operate and maintain, ideal for complex tasks and reducing labor costs.

Packaging

Ultrasonic Welding for Different Industries

Ultrasonic welding is widely used in welding plastic products, including industries automotive, consumer electronics, medical, toys, packaging, and so on, especially where long-lasting, strong, and great-looking connections are needed.

FAQs

Here are frequently asked questions to consider before choosing an ultrasonic welder for your plastic products.

We are Internationally Certified

Our ultrasonic plastic welding machines are certificated with CE,ISO and ROSH. They all meet international standards.

Customer Reviews

Quote Now

Quote Now